Toymaker Mattel has announced that it aims to ensure that all of its iconic Matchbox die-cast cars, playsets and packaging will be made with 100 per cent recycled, recyclable or bio-based plastic by 2030.

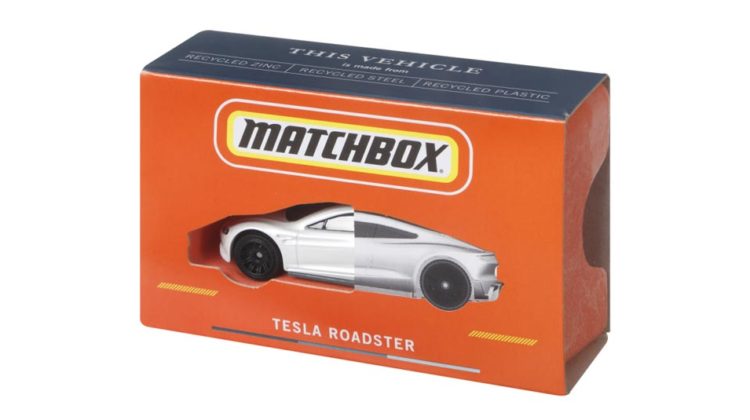

In order to illustrate these principles, Mattel unveiled its new Matchbox Tesla Roadster, the first of its die-cast vehicles to be made from 99 per cent recycled materials and certified carbon neutral by Natural Capital Partners, with carbon-offset credits going towards the preservation of grasslands in Colorado and Montana. The car, which Mattel describes as its ‘blueprint for the future’, is made from recycled zinc, steel and plastic.

The company has also revealed plans aimed at helping children to ‘think green’ through an eco-friendly-themed approach to play that features an expanded range of e-vehicles and e-vehicle chargers in Matchbox fuel station playsets.

Matchbox products will now be sold in zero-plastic packaging made from paper and wood-fibre materials certified by the Forest Stewardship Council and will offer enhanced consumer recycling and waste recovery through a mixture of product design and packaging labelling.For example, the electronics in playsets will be consolidated into a single, easily removable module to help make the e-waste recycling process easier. Matchbox is also exploring ways to reduce energy use, carbon emissions and waste production in its operations.

According to Jon Marine, Mattel’s vice president of product development, the company is in the process of re-engineering a number of its plastic components so that they can be made using recycled materials. Mattel is taking a holistic approach, he said, taking in part design and engineering, the design of injection moulds and changes to the manufacturing process itself.

‘Since the inception of the modern-day die-cast car nearly 70 years ago, Matchbox has been using design and innovation to connect kids with the real world around them through play,’ said Roberto Stanichi, the global head of vehicles at Mattel. ‘Matchbox is committing to using 100 per cent recycled, recyclable or bio-based plastic materials to do our part in addressing the environmental issues we face today, and empower the next generation of Matchbox fans to help steer us towards a sustainable future.’