A team of engineers at the University of Nebraska-Lincoln has come up with a novel way of using droplets of liquid metal to dissipate heat and prevent overheating in devices that use microelectronics. The new technique has the potential to revolutionise the design of wearable technology, soft robotics and other microelectronics-packed applications.

‘As computing power increases, thermal dissipation becomes an increasingly important factor,’ said Eric Markvicka, assistant professor of mechanical and materials engineering.

Many wearable devices and other smart technologies feature malleable, elastic materials that reduce weight and increase comfort but also trap heat. In order to address this problem, Markvicka and other engineers have tried loading the insulating materials with tiny droplets of liquid metal, which naturally conduct heat and hence can carry it away from the microelectronics that generate it. Although the approach has worked, the density of droplets required to effectively enhance conductivity typically adds an impractical amount of weight.

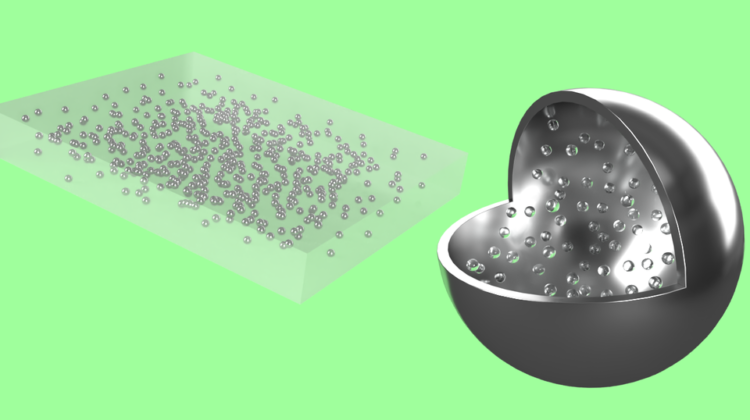

In a new study, however, Markvicka’s team has shown that when gallium-based droplets are embedded in a silicone material – and, crucially, the droplets themselves are embedded with microscopic spheres of hollow glass – the boost in heat dissipation is retained, without sacrificing the material’s lightweight pliability.

‘It is still soft and rubbery but has a thermal conductivity approaching [that of] some rigid metals, like titanium or stainless steel, with approximately half the density of those metals,’ Markvicka said. ‘This combination of properties makes the material unique and interesting.’

The researchers tested versions of the silicone whose liquid metal droplets housed varying volumes of the hollow glass, from zero up to 50 per cent. The 50 per cent increase in volume led to a 35 per cent decrease in the material’s overall density and just a 14 per cent drop in thermal conductivity; the latter was starting at a higher baseline than silicone that lacked the liquid metal.

With the aid of prior modelling work, the team then developed what Markvicka described as a ‘contour map’ to guide the future tailoring of soft materials that rely on the team’s Russian nesting doll approach. One axis of the map accounts for the volume of liquid metal droplets in a material, while the other axis quantifies the volume of glass microspheres in the droplets. Modifying the volume of glass microspheres alone, the map showed, can alter the material’s density while leaving the thermal conductivity almost completely unchanged. Modifying the ratios of both glass and liquid metal, meanwhile, can change the thermal conductivity without affecting the density.

‘So, we’ve been able to show that we can now independently control thermal conductivity and density in these composites, which has never been shown before,’ said Markvicka.

According to Markvicka, a soft but thermally conductive material could benefit emerging technology in several ways – for example, by helping to alleviate limitations on the computing power of microelectronics that are squeezed into wearable technology, smoothing the path to faster devices with more functionality.

Engineers of larger-scale digital technology, such as computers and gaming consoles, might also find it useful when crafting so-called interface materials, which carry substantial amounts of heat from, say, processors to liquid coolants. The PlayStation 5 console, for instance, already uses liquid metal for that purpose.

There are also potential applications in thermoregulatory garments that monitor a wearer’s skin temperature and then supply or remove heat accordingly. ‘A lot of the big tool companies have these heated jackets and gear to help workers stay warm in cold environments,’ Markvicka said. ‘This material could function as a passive heat spreader to achieve more uniform heating throughout a jacket and eliminate hot spots, without restricting the motion of the wearer. Anything the human body interacts with, there could be applications for this material.’

The team’s proof of concept has been published in the journal Small.