A new study by an international team of engineers has uncovered the reason why fish fins are both strong and flexible. According to the researchers, the findings could one day inspire new designs for robotic surgical tools or airplane wings that change their shape at the push of a button.

Fish fins are remarkable because they can achieve incredible feats of dexterity despite the fact that they don’t contain a single muscle. (Fish move their fins by twitching groups of muscles found at their base.)

‘If you look at a fin, you’ll see that it’s made of many stiff “rays”,’ said Francois Barthelat, a professor in the Paul M Rady Department of Mechanical Engineering at the University of Colorado Boulder, who led the study. ‘Each of those rays can be manipulated individually just like your fingers, but there are 20 or 30 of them in each fin.’

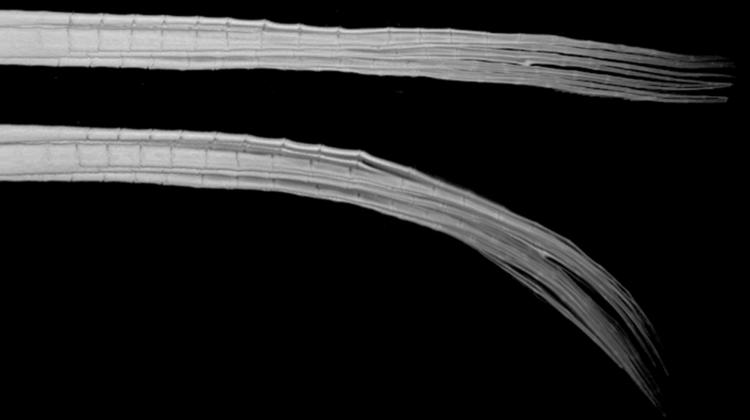

Barthelat and his collaborators used a range of techniques, including computer simulations and 3D-printed materials, to investigate the biomechanics of these agile structures. They found that the key appears to lie in their unique design.Each of the rays within a fin consists of two layers made up of segments, known as hemitrichs, which are made from a stiff, mineralised material. ‘Until recently, the function of those segments hadn’t been clear,’ Barthelat said.

The two layers of hemitrichs sandwich an inner layer of spongy collagen. Together, these layers give the fins the perfect balance between bouncy and stiff. ‘You get this dual capability where fins can morph, and yet they’re still quite stiff when they push water,’ he said.

Materials that are both stiff and flexible are extremely useful for engineering design.Airplane designers, for example, would love to be able to develop wings that can morph on command, improving manoeuvrability while still keeping the planes in the air.

‘Airplanes do this now, to some extent, when they drop their flaps,’ Barthelat said. ‘But that’s in a rigid way. A wing made out of morphing materials, in contrast, could change its shape more radically and in a continuous manner, much like a bird.’

Using computer simulations, the researchers revealed how the segments were crucial to the fins’ mechanical properties. As Barthelat explained, fins made entirely of collagen would bend too easily, reducing their ‘traction’ in the water, while rays made up of solid, non-segmented hemitrichs would be far too stiff.

‘All of the segments, essentially, create these tiny hinges along the ray,’ Barthelat said. ‘When you try to compress or pull on those bony layers, they have a very high stiffness. This is critical for the ray to resist and produce hydrodynamic forces that push on water. But if you try to bend individual bony layers, they’re very compliant, and that part is critical for the rays to deform easily from the base muscles.’

When the researchers tested their theory using a 3D printer to produce model fish fins made from plastic, some with hinges built in and some without, they found that the segmented design provided better combinations of stiffness and morphing capabilities.

The research has been published in Science Robotics.