A team of Princeton University and Georgia Tech researchers has created a new type of porous structure, designed to mimic bone, wood and other natural materials, that is lighter than traditional products and can be strategically inserted into products to provide increased stiffness in areas with high demand.

The structures feature spinodal microstructures – networks of specially designed holes that can be tuned to achieve optimised behaviour at the macroscale. Many natural materials, including bone, animal horn the skeletons of sand dollars and wood, are full of holes. The empty spaces make the materials light and, in some cases, allow bodily fluids to move through the pores. In bones, these spaces allow for a remodelling process that makes the bone more or less dense in response to physical demands. Creating synthetic materials with similar properties has long been a challenge for engineers.

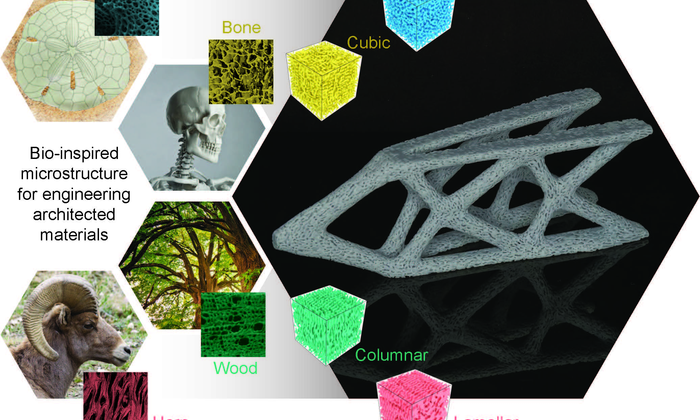

In the new study, the researchers mimicked these natural materials by designing microstructures with holes of different sizes, shapes and orientations. The new objects are known as architected materials. Their performance is customisable based on the relation between material and geometry. The holes can be shaped like spheres (like those in sand dollar skeletons), diamonds (bone), columns (wood) or lentils (horn). By varying the shape, the researchers can imbue the material with stiffness in different directions. They controlled the material’s density by changing the holes’ size and altered the holes’ orientation within an object to increase stiffness in regions under strain.

‘You have the actual structure and the microstructure working together to get superior performance,’ said Fernando Vasconcelos da Senhora, a graduate student at Georgia Tech.

The researchers designed and 3D-printed a facial implant, such as the kind used to repair a major facial injury from a car accident, using the new material. Currently, surgeons use plastic or titanium to create porous implants that allow bone to regrow through holes, but the implants don’t have the same tunability achievable with spinodal architectures. The researchers combined sections with column- and lentil-shaped holes to create an implant that was stiff enough to withstand the forces of chewing and had the right-sized holes to promote bone growth and healing.

According to the researchers, the technique makes it possible to create implants made up of several different types of material, allowing designers to fine-tune performance by varying the combination of geometry and material.

‘It’s not the base material that is better; it’s the microscale features that are better,’ said Emily Sanders, an assistant professor of mechanical engineering at Georgia Tech. ‘In theory, we could make the scaffolds out of any material – most appropriate would be to explore biocompatible materials.’

A key aspect of the materials’ success is the seamless transitions from one type of microstructure to another within the same object. Abruptly switching between microstructures without connecting the network of pores would cause the material to split along the seams. Materials made with spinodal microstructures are also less likely to have weak spots because the holes occur randomly, instead of in regular patterns.

‘A major part was figuring out how to take advantage of the manufacturing platform and [work out] mathematically the structure of these architected materials and then link the two together so that we could actually fabricate something,’ said Sanders.

The team is now exploring additional uses for the microstructures. Currently, the technology is at the prototype stage, but they are eager to test the properties of the materials more fully. ‘I’m interested in understanding the fundamental questions about how these architected materials behave,’ Sanders said.

The research has been published in Advanced Materials.