Researchers from the University of Minnesota Twin Cities and Kiel University in Germany have discovered a new ‘recipe’ that could be used to produce shape-shifting ceramic materials. Such materials could pave the way for improvements in everything from medical devices to electronics.

Ceramics have a number of properties that make them well suited to use in electronics; depending on their composition, they may be semiconducting, superconducting, ferroelectric or insulating. The fact that they are also non-corrosive makes them suitable for use in a wide variety of other products, including spark plugs, fibre-optics, medical devices, space shuttle tiles, chemical sensors and skis. However, conventional ceramics are brittle, shattering when subjected to the slightest deformation.

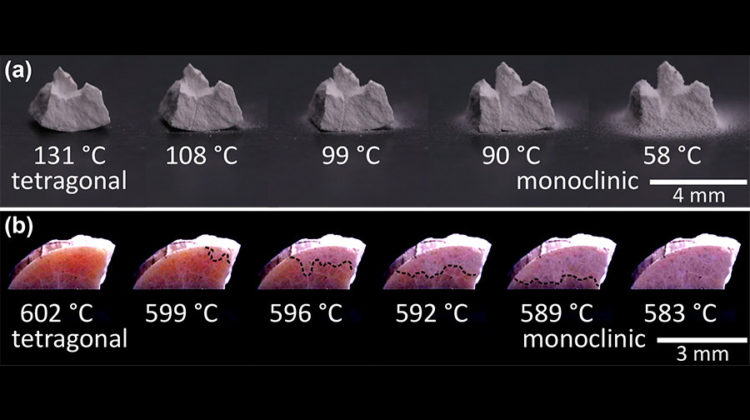

At the other end of the materials spectrum sit so-called shape-memory alloys, which are among the most deformable or re-shapable materials known. The origin of this shape-shifting behaviour is what’s known as a solid-to-solid phase transformation. Unlike crystallisation-melting-recrystallisation transformations, crystalline solid-solid transitions take place solely in the solid state – by changing temperature (or pressure), a crystalline solid can be transformed into another crystalline solid without going through a liquid phase. When the researchers set out to produce a reversible shape-memory ceramic, they first tried using a recipe that has worked for the discovery of new metallic shape-memory materials, which involves a delicate tuning of the distances between atoms by compositional changes, so that the two phases fit together well. However, rather that improving the deformability of the ceramic, the recipe resulted in some specimens exploding when they passed through the phase transformation, while others gradually fell apart into a pile of powder, a phenomenon the researchers termed ‘weeping’.

Moving to another composition, they hit paydirt, the novel ceramic transforming back and forth between phases, much like a shape-memory material. They then determined that the mathematical conditions under which reversible transformation occurs can be applied widely, providing a way forward towards the production of a paradoxical shape-memory ceramic.

‘We were quite amazed by our results. Shape-memory ceramics would be a completely new kind of functional material,’ said Richard James, a professor in the University of Minnesota’s Department of Aerospace Engineering Mechanics. ‘There is a great need for shape memory actuators that can function in high temperature or in corrosive environments. But what excites us most is the prospect of new ferroelectric ceramics. In these materials, the phase transformation can be used to generate electricity from small temperature differences.’

The research has been published in Nature.