Researchers at UCLA have made a breakthrough that could dramatically extend the lifespan of hydrogen fuel cells, making them a more viable clean energy source that can help bring sustainable, long-haul trucking closer to reality.

For trucks and heavy-duty vehicles that must travel long distances without frequent, time-consuming charging stops, batteries often fall short. Hydrogen fuel cells – which can be refuelled as quickly as traditional gasoline – offer a cleaner, more efficient alternative.

Led by Yu Huang, a professor of materials science and engineering at the UCLA Samueli School of Engineering, the research team has developed a new catalyst design that’s capable of pushing the projected fuel cell catalyst lifespans to 200,000 hours, which is nearly seven times the US Department of Energy’s target for 2050. The research marks a significant step toward the widespread adoption of fuel cell technology in heavy-duty vehicles, such as long-haul tractor trailers.

Although medium- and heavy-duty trucks make up only about five per cent of vehicles on the road, they are responsible for nearly a quarter of greenhouse gas automobile emissions, according to federal estimates. This makes heavy-duty applications an ideal entry point for polymer electrolyte membrane fuel cell technology.

Because fuel cells are significantly lighter than batteries, they require less energy to move the vehicles. With a projected power output of 1.08 watts per square centimetre, fuel cells featuring the new catalyst can deliver the same performance as conventional batteries that weigh up to eight times more. This difference is especially relevant for heavy-duty vehicles, which not only carry substantial cargo but also tend to be much heavier than standard vehicles. In addition, building a national hydrogen-refuelling infrastructure would likely require less investment than establishing an electric vehicle-charging network across the country.

Fuel cells work by converting the chemical energy stored in hydrogen into electricity, emitting only water vapour as a byproduct. This has made them a promising solution for cleaner transportation. However, the slow chemical reaction for the energy conversion has been a challenge, requiring a catalyst to achieve practical speeds.

While platinum-alloy catalysts have historically delivered a superior chemical reaction, the alloying elements leach out over time, diminishing catalytic performance. The degradation is further accelerated by the demanding voltage cycles required to power heavy-duty vehicles.

To address this challenge, the UCLA team has engineered a durable catalyst architecture with a novel design that shields platinum from the degradation typically observed in alloy systems.

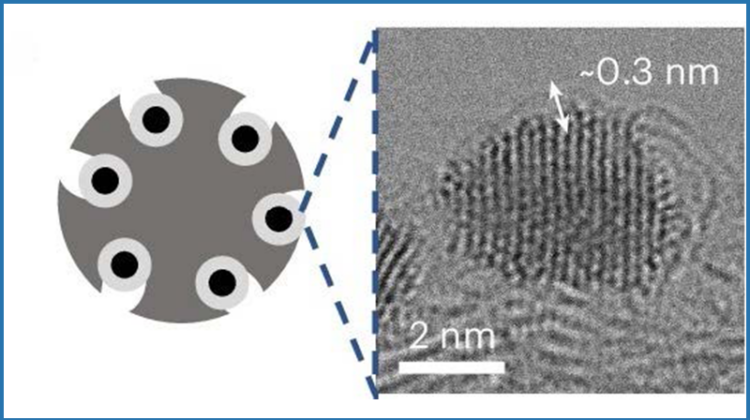

The researchers began by embedding ultrafine platinum nanoparticles within protective graphene pockets. Composed of a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, graphene is the thinnest known material. Despite its atomic thinness, it’s incredibly strong, lightweight and highly conductive. These graphene-encased nanoparticles were then nested inside the porous structure of Ketjenblack, a powdery carbon material. This ‘particles-within-particles’ design provides long-term stability while preserving the high catalytic activity essential for efficient fuel cell performance.

‘Heavy-duty fuel cell systems must withstand harsh operating conditions over long periods, making durability a key challenge,’ said Huang, who holds the Traugott and Dorothea Frederking Endowed Chair at UCLA Samueli. ‘Our pure platinum catalyst, enhanced with a graphene-based protection strategy, overcomes the shortcomings of conventional platinum alloys by preventing the leaching of alloying elements. This innovation ensures that the catalyst remains active and robust, even under the demanding conditions typical of long-haul applications.’

The new catalyst exhibited a power loss of less than 1.1 per cent after an accelerated stress test involving 90,000 square-wave voltage cycles designed to simulate years of real-world driving, where even a ten per cent loss is typically considered excellent. These superior results project fuel cell lifetimes exceeding 200,000 hours, far surpassing the DOE’s target of 30,000 hours for heavy-duty proton exchange membrane fuel cell systems.

By successfully addressing the dual challenges of catalytic activity and durability, the UCLA researchers’ innovative catalyst design holds great promise for the adoption of hydrogen-powered heavy-duty vehicles — an essential step toward reducing emissions and improving fuel efficiency in a sector that accounts for a substantial share of transportation energy use.

The team’s findings built on its earlier success in developing a fuel cell catalyst for light-duty vehicles that demonstrated a lifespan of 15,000 hours – nearly doubling the DOE’s target of 8,000 hours.

UCLA’s Technology Development Group has filed a patent on the technology.

The research has been published in Nature Nanotechnology.