Researchers in the Additive Manufacturing Lab at Simon Fraser University in British Columbia, Canada, are using origami to create innovative 3D-printable technologies to aid in the fight against COVID-19 and help doctors to identify and diagnose health conditions.

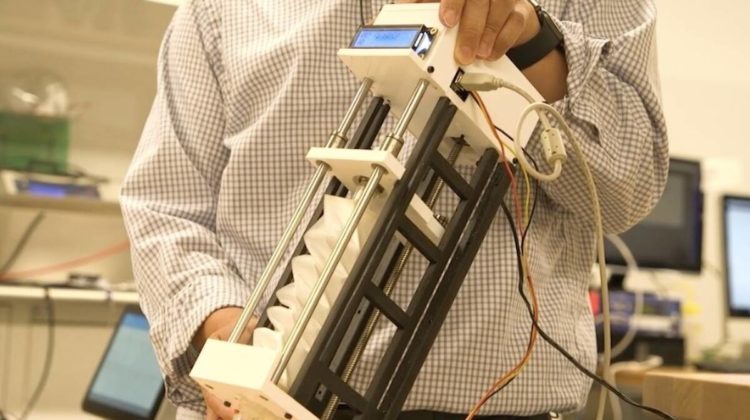

Associate Professor Woo Soo Kim of the School of Mechatronic Systems Engineering and his team have developed a low-cost, portable 3D-printed ventilator that’s driven by a patented 3D-printed origami tube.

The ventilator assists a patient’s breathing by contracting a 3D-printed origami tube, rather than compressing a conventional bag-valve mask. The design reduces the machine’s overall size while also increasing its mechanical strength. The 3D-printed design and the use of lightweight materials also lowers the production cost.

‘In our portable origami ventilator, more than 95 per cent of components can be 3D printable, that’s why it is really cost-efficient,’ Kim said. ‘Other portable ventilators can cost more than CA$2,000, but our 3D-printed ventilator can be produced for about CA$200.’

According to Kim, the compact, lightweight design, combined with the low production cost makes the portable ventilator ideal for use outside hospital settings, such as in long-term care homes or in remote rural areas and developing countries.

The team has partnered with Vancouver-based ventilator manufacturer Pantheon Design and Delta-based 3D-printing company Tinkerine to further develop the design while also seeking further investment and development partners in the hope of mass producing the ventilator.

Details of the design, which was recently evaluated by a local team of respiratory therapists, have been published in Flexible and Printed Electronics.

Kim is also developing 3D origami dry electrodes capable of detecting and monitoring physiological signals such as heartbeat, breathing, temperature and muscle movement for use in monitoring patient health. He envisions the technology potentially being used for remote monitoring through a robot helper.

‘The dry electrode doesn’t need to be equipped with the sensing robot – it can be used in a hospital setting to replace the wet gel type electrode for electrophysiology such as electrocardiogram or blood pressure measurement applications,’ Kim said. ‘Dry electrodes are just one of the technologies under this portfolio of 3D origami technologies we are developing here at SFU.’