Shropshire-based prototyping and production company Protolabs has launched a new rapid online method for analysing 3D-printed parts that will help to ensure that a part is suitable for manufacturing.

According to Protolabs, the firm has been using the design-for-manufacturability (DFM) analysis to support customers using its CNC and injection moulding services. It said that the development brings the benefits of speed and reassurance to its 3D-printing service.

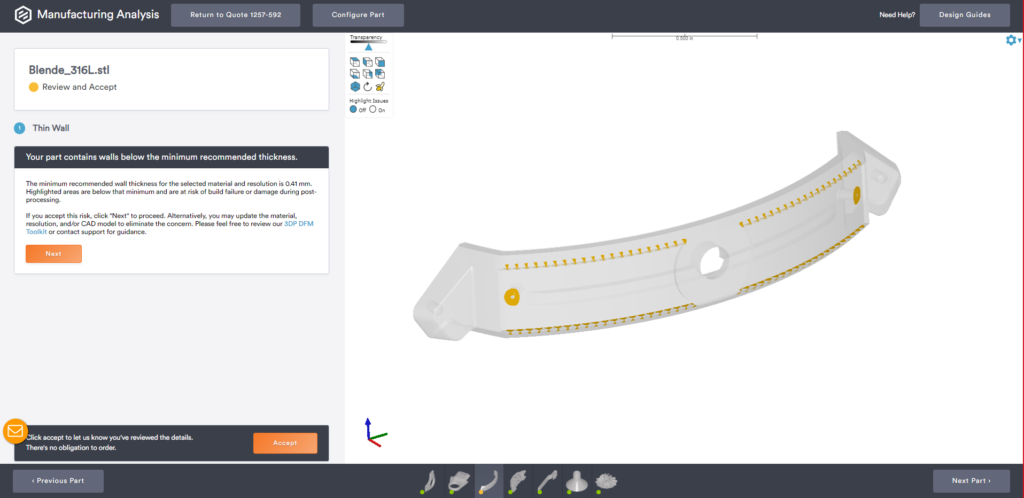

‘Additive manufacturing is a brilliant technology, allowing engineers to produce complex parts that were previously too difficult to achieve,’ said Andrea Landoni, Protolabs’ 3D-printing product manager. ‘While the technology offers great flexibility, there are a few limitations that engineers must be aware of and the DFM analysis provides that guidance in seconds. The system will instantly highlight all of the issues to the user, whether they are critical, such as parts that are too large to be produced, or non-critical, like dimensions that are close to certain thresholds like wall thickness and may not form completely.

‘We understand the importance of speed, but ensuring that parts are correct, high quality, and delivered rapidly is critical,’ she continued. ‘Instant analysis means you can have all the advantages of additive manufacturing with even more certainty without sacrificing speed.’

Protolabs said that DFM processes eliminate lost-time incidents for most common issues, preventing engineers from proceeding with their order only to discover that there has been an issue hours later. While the vast majority of problems are solved, there are circumstances where the user may still require further support.

‘Protolabs understand that specific projects require technical consultancy to solve complex issues,’ Landoni said. ‘In these circumstances, our application engineers are still on hand to overcome these challenges and accelerate the process. The DFM analysis supports our application engineers by reducing the number of projects they need to get involved in, allowing them to interact with more customers who require their support even faster.’