A research team at the Harbin Institute of Technology, China has developed a compact robotic finger for dexterous hands that is capable of withstanding physical impacts in its working environment.

For decades, researchers have attempting to design robotic hands that mimic the dexterity of human hands in the ways that they grasp and manipulate objects. However, these earlier robotic hands have generally been unable to withstand the physical impacts that can occur in unstructured environments.

Robots often work in environments that are unpredictable and sometimes unsafe. Physical collisions are unavoidable when multi-fingered robotic hands are required to work in unstructured environments in which obstacles may move quickly, and can cause significant damage. The research team worked to create a robotic finger that could mimic the human finger in dexterity and also in its ability to absorb and withstand physical impacts.

‘This will enable the dexterous hand to have better mechanical robustness, thus solving the problem that the rigid driven dexterous hand is easily damaged by physical collisions in unstructured environments,’ said Yiwei Liu, a professor who works in the State Key Laboratory of Robotics and System at the Harbin Institute of Technology.

In the human body, the muscles’ natural stiffness and flexibility varies depending on the task at hand. Roboticists attempt to mimic this using variable-stiffness actuator systems, which are typically driven by two actuators. This means that the robotic hand system must have two sets of decelerators, actuation devices and sensors, increasing the variable stiffness actuator’s complexity, weight and volume.

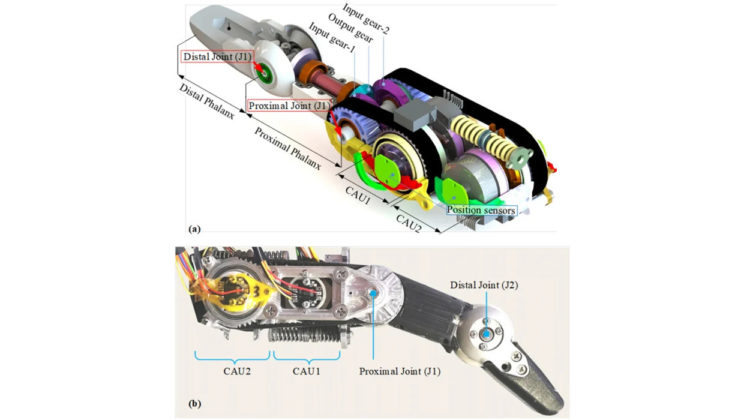

To overcome these challenges, the research team developed an antagonistic variable-stiffness finger mechanism. This finger is based on gear transmission, which tends to be more reliable and easier to manufacture and maintain than the current cable-driven dexterous hands. The mechanically robust finger is based on the concept of mechanical passive compliance, where the contact forces between a robotic manipulator and a stiff environment are controlled. The mechanical finger can absorb physical impacts while also possessing the ability to adjust its stiffness, depending on the requirements of the task it’s performing. The advantage of this finger mechanism is that it provides an adjustable-stiffness function and a very compact structure without the weight and complexity of additional actuators.

The finger prototype developed by the team weighs 480 grams and is fabricated from alloys and 3D-printed material. The team carried out a series of grasping and manipulation tests on the finger using a variety of typical objects of different sizes and shapes, including cylinders, rectangular prisms and spheres.

The team plans to improve the finger’s stiffness-adjustment range while also working to make it lighter and more compact. ‘This research is of great importance to improving the manipulation level of dexterous hands in unstructured environments or physical interacting tasks,’ said Liu.

The research has been published in Frontiers of Mechanical Engineering.