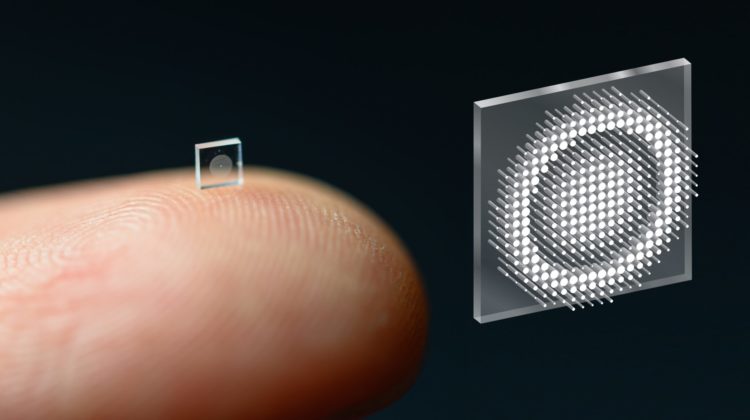

Researchers at Princeton University and the University of Washington have designed an ultracompact camera the size of a coarse grain of salt that’s capable of producing crisp, full-colour images on a par with a conventional compound camera lens 500,000 times larger in volume. According to the research team, the system could enable minimally invasive endoscopy with medical robots and improve imaging for other robots with size and weight constraints.

Traditional cameras use a series of curved glass or plastic lenses to bend light rays into focus. The new optical system, on the other hand, relies on a so-called metasurface, which can be produced much like a computer chip.Just half a millimetre wide, the new metasurface is studded with 1.6 million cylindrical posts, each roughly the size of the human immunodeficiency virus.

The posts, each of which has a unique geometry, function like optical antennae and correctly shape the entire optical wavefront. Machine-learning-based algorithms then enable the combination of the posts’ interactions with light to create an image.

The integrated design of the optical surface and the signal processing algorithms that produce the image helped to boost the camera’s performance in natural-light conditions; current metasurface cameras require pure laser light or other ideal conditions to produce high-quality images. They have also suffered from major image distortions, small fields of view and limited ability to capture the full spectrum of visible light (known as RGB light).

‘It has been a challenge to design and configure these little microstructures to do what you want,’ said Ethan Tseng, a computer science PhD student at Princeton who co-led the study. ‘For this specific task of capturing large field of view RGB images, it was previously unclear how to co-design the millions of nano-structures together with post-processing algorithms.’

Co-lead author Shane Colburn, a PhD student at the University of Washington, solved this problem by creating a computational simulator to automate the testing of different nano-antenna configurations, developing a model to efficiently approximate the metasurfaces’ image-production capabilities with sufficient accuracy in order to speed up the process.

The metasurfaces are based on silicon nitride, a glass-like material that’s compatible with the standard semiconductor-manufacturing methods used for computer chips, which means that a given metasurface design could be easily mass-produced at lower cost than the lenses in conventional cameras.

The researchers are now attempting to add more computational abilities to the camera itself. Beyond optimising the image quality, they would like to add capabilities for object detection and other sensing modalities relevant for medicine and robotics.

The research has been published in Nature Communications.