Mechanical engineering researchers at the UCLA Samueli School of Engineering have designed a mattress that helps prevent bedsores by alternating pressure across the body and, at times, increasing peak pressure rather than reducing it to restore blood flow.

Common bedsore treatment protocols involve moving and turning bedridden individuals every two hours. However, this recommendation is both costly and cumbersome, leading to inconsistent care and potential injuries for caregivers.

Pressure ulcers, also known as bedsores, arise from consistent pressure on a body part that impedes the blood flow. They are particularly troublesome for people who are immobilised and lying in bed for long periods. Bedsores are a serious health concern, causing more than 60,000 deaths annually in the USA, according to the Agency for Healthcare Research and Quality, part of the Department of Health and Human Services. In acute care facilities across the country, 2.5 million people are treated for bedsores each year at a cost of US$11billion – exceeded only by the treatment costs for cancer and cardiovascular disease. Although they can develop wherever prolonged pressure is applied, bedsores are most common on skin over bony areas such as the sacrum, heel, elbow and knee.

‘We set out to build an affordable, versatile and practical mattress that would be much more effective in preventing pressure ulcers,’ said Jonathan Hopkins, a professor of mechanical and aerospace engineering at UCLA Samueli.

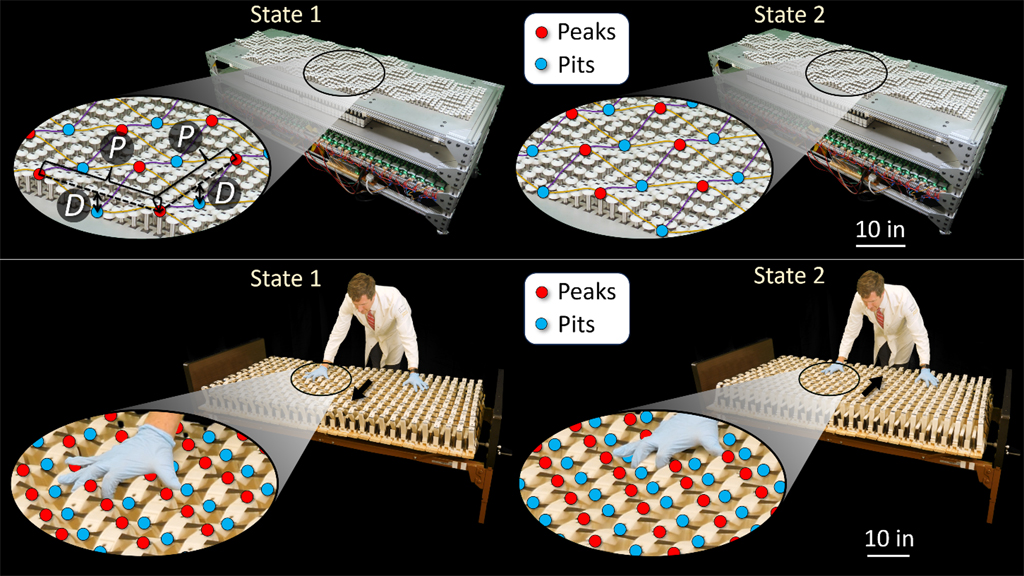

Hopkins’ team previously created a bed featuring 1,260 linear actuators, which can be independently controlled to test how different surface patterns affect blood flow and pressure. The research findings led to the design of the alternating-pressure mattress that utilises a lattice of compliant mechanisms, which enables smooth transitions between two alternating chequerboard-like surface patterns while minimising actuation energy and cost.

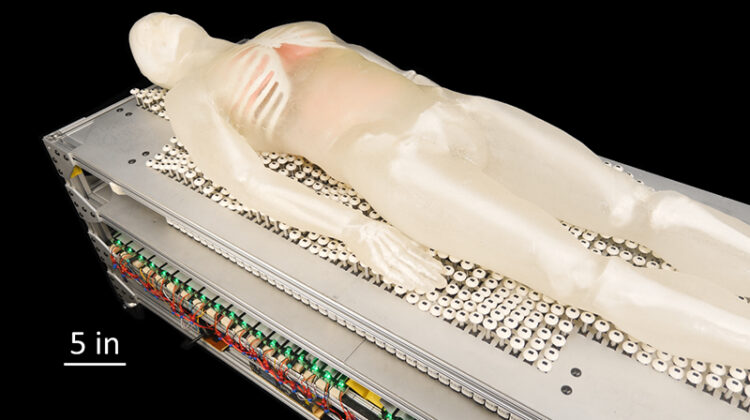

To demonstrate the performance of their mattress, the researchers tested their design on a standard bedframe using a sensor-equipped foam pad on top of the mattress and a 100-kilogram anatomical dummy. The sensors tracked pressure levels across the body as the mattress shifted between its two states of pressure, relieving pressure at the troughs and applying pressure to the peaks. The pressure data were capped at the average occlusion pressure threshold of 32 millimetres of mercury – an average pressure beyond which blood and lymphatic fluids are prevented from flowing into tissue, causing bedsores.

Nearly 30 balancing springs are incorporated into the design so that the transition between the two states of pressure will be smooth and gentle. The researchers also developed a software tool using a patient’s height and weight to determine the optimal number and placement of balancing springs needed to minimise the force required to actuate the mattress for patients of varying sizes. By attaching a few low-power linear actuators to the structure, the mattress can transition between states automatically. But it can also be set in motion by a caregiver with little effort.

‘Imagine that the black squares of a chequerboard rise up to support the patient while the white squares retract to provide pressure relief at their locations,’ Hopkins said. ‘Then, after some time, the white squares rise upward and the black squares sink to alleviate the pressure just applied – the peaks become the pits, then vice-versa. That is cyclically repeated with the hope of ensuring there’s no place where blood flow is persistently occluded.’

Findings from the research also suggested that increasing pressure differences – within comfort limits – more effectively restored circulation to areas under pressure. So instead of reducing overall peak pressure, the team focused on ensuring an increased pressure difference between the raised and lowered states and alternating which body parts bear the most force on the mattress at any given time. The alternating pressure means that the body’s points of contact under pressure are minimised to no more than half of the time.

Current alternating-pressure mattresses designed to prevent bedsores often use inflatable air chambers that adjust the overall pressure of the mattress at regular intervals. The UCLA system uses embedded sensors and a compliant mechanism to vary pressure locally across the mattress surface. This allows for finer pressure redistribution informed by real-time data and tailored to individual user characteristics, such as height and weight.

The mattress, with most of its parts cleanable and the sensor-embedded foam pad replaceable, also allows for improved airflow underneath a patient and helps mitigate fluid build-up often linked to uneven pressure distribution.

The UCLA Technology Development Group holds a patent on the concept, with additional patent applications pending for the mechanisms. The prototype is currently undergoing volunteer testing at a professional lab to assess its effectiveness in real-world settings.

The research has been published in Science Robotics.