A team of engineers at the Augmented Listening Laboratory at the University of Illinois Urbana-Champaign is creating a ‘cocktail party’ of 3D-printed, humanoid robots that can listen and talk to each other. Realistic talking (and listening) heads such as these are crucial for investigating how humans receive sound and for developing audio technology.

Algorithms used to improve human hearing must consider the acoustic properties of the human head. For example, hearing aids adjust the sound received at each ear to create a more realistic listening experience. For the adjustment to succeed, an algorithm must realistically assess the difference between the arrival time at each ear and amplitude of the sound.

It’s also important to study human listening in natural environments, such as cocktail parties, in which numerous conversations occur at once. ‘Simulating realistic scenarios for conversation enhancement often requires hours of recording with human subjects. The entire process can be exhausting for the subjects, and it is extremely hard for a subject to remain perfectly still in between and during recordings, which affects the measured acoustic pressures,’ said Austin Lu, a student member of the team. ‘Acoustic head simulators can overcome both drawbacks. They can be used to create large data sets with continuous recording and are guaranteed to remain still.’

Since researchers have precise control over the simulated subject, they can adjust the parameters of the experiment and even set the machines in motion to simulate neck movements.

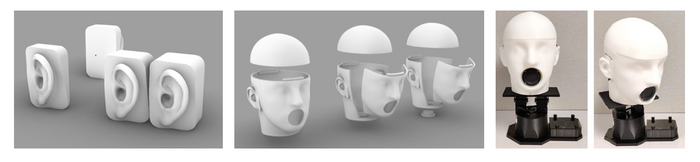

In a feat of design and engineering, the heads are 3D-printed into components and assembled, enabling customisation at low cost. The highly detailed ears are fitted with microphones along different parts to simulate both human hearing and Bluetooth earpieces. The ‘talkbox’, or mouthlike loudspeaker, closely mimics human vocals.

To facilitate motion, the researchers paid special attention to the neck. Because the 3D model of the head design is open source, other teams can download and modify it as needed. The diminishing cost of 3D printing means there is a relatively low barrier for fabricating these heads.

‘Our acoustic head project is the culmination of the work done by many students with highly varied technical backgrounds,’ said Manan Mittal, a graduate researcher with the team. ‘Projects like this are due to interdisciplinary research that requires engineers to work with designers.’

The Augmented Listening Laboratory has also created wheeled and pully-driven systems to simulate walking and more complex motion.