A team of researchers from Nagoya University in Japan has developed a loop heat pipe (LHP) that can transport up to ten kilowatts of heat without the need for electricity, an unprecedented level of heat transport capability.

LHPs have been used in manned space flights, electric vehicles (EVs), meteorological satellites and home electronic appliances. The significant increase in performance of the new LHP design is related to enhancements in the evaporator structure. These improvements led to an 18 per cent reduction in size, a 1.6-fold increase in heat transport capability and a fourfold increase in heat transfer efficiency compared to the previous LHP developed by Nagoya University.

‘This LHP is unprecedented in transporting such a large amount of heat without electricity, achieving the world’s largest non-electric heat transport,’ said Professor Hosei Nagano, a senior researcher involved in the project. ‘This eliminates the need for the electricity previously consumed by conventional mechanical pumps, allowing for near-perpetual heat transport without electricity.’

The EV industry is seeing a rising demand for energy-efficient cooling methods because of companies’ growing awareness of their carbon footprint. LHPs help EVs improve overall efficiency by providing cooling that doesn’t require electricity, reducing the need for electrical power.

‘For electric vehicles, maintaining the inverter temperature is crucial for optimal performance,’ explained Shawn Somers-Neal, a graduate student involved in the project. ‘Traditional cooling methods for inverters require energy, but our LHP maintains temperature without electricity. This leads to an increase in efficiency while being able to handle the high heat loads required in industry.’

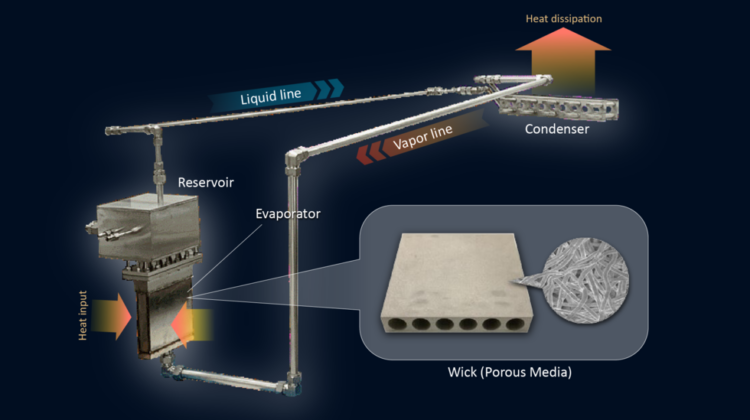

In an LHP, a working fluid and a porous material called a wick are used to transport heat efficiently over long distances. The wick draws the working fluid to the surface through capillary action. When heat is applied to the evaporator, the fluid on the wick’s surface absorbs the heat and turns into vapour. This vapour travels to a condenser, where it releases the heat and condenses back into liquid. The liquid then returns to the compensation chamber, where it contacts the wick again, which draws it back to the surface and continues the cooling cycle.

The group enhanced the wick section of the LHP by making it thinner, longer and wider while preserving its high-quality porous properties. They also improved heat transport capabilities by narrowing the channels that allow the vapour to escape from the evaporator and adding additional channels on the sides, thereby increasing the total number of channels.

‘The uniqueness of the LHP is the shape, quality and size of the wick, and the overall performance of the LHP. Usually, when making larger wicks, the quality decreases, but the quality of this wick is similar to that of smaller wicks,’ explains Professor Nagano. ‘The wick has cores that help reduce the thickness, leading to less pressure drop and lower operating temperatures.’

The newly developed LHP demonstrated a heat transfer efficiency of more than four times that of existing LHPs during testing. The design was so effective that it transported waste heat over a distance of 2.5 metres without power, using the capillary force generated by the wick. This set a record for non-powered heat transport.

‘This pioneering LHP technology is expected to revolutionise energy conservation and carbon neutrality across multiple fields, including factory waste heat recovery, solar heat utilization, electric vehicle heat management and data centre cooling,’ Somers-Neal said. ‘The effective saving of factory waste heat marks a significant step towards sustainable energy solutions.’

The research has been published in the International Journal of Heat and Mass Transfer.