A pair of MIT engineers has come up with a general design tool that roboticists can be used to speed up the development of autonomous systems. The engineers’ optimization code can be applied to simulations of virtually any autonomous robotic system and used to automatically identify how and where to tweak the system to improve the robot’s performance.

Robotic systems are the product of ad hoc design processes that are specific to that particular system. In designing an autonomous robot, engineers must run countless trial-and-error simulations, often informed by little more than intuition. These simulations are tailored to a particular robot’s components and tasks, in order to tune and optimise its performance. In some respects, designing an autonomous robot today is like baking a cake from scratch, with no recipe or prepared mix to ensure a successful outcome.

Charles Dawson, an MIT graduate student, and ChuChu Fan, assistant professor in MIT’s Department of Aeronautics and Astronautics, realised the need for a general optimisation tool after observing a wealth of automated design tools available for other engineering disciplines.

‘If a mechanical engineer wanted to design a wind turbine, they could use a 3D CAD tool to design the structure, then use a finite-element analysis tool to check whether it will resist certain loads,’ Dawson said. ‘However, there is a lack of these computer-aided design tools for autonomous systems.’

Normally, a roboticist optimises an autonomous system by first developing a simulation of the system and its many interacting subsystems, such as its planning, control, perception and hardware components. She must then tune certain parameters of each component and run the simulation forward to see how the system would perform in that scenario.

Only after running numerous scenarios through trial and error can a roboticist then identify the optimal combination of ingredients to yield the desired performance. It’s a tedious, overly tailored and time-consuming process that Dawson and Fan sought to turn on its head. ‘Instead of saying, “Given a design, what’s the performance?” we wanted to invert this to say, “Given the performance we want to see, what is the design that gets us there?”’ Dawson explained.

The researchers developed an optimisation framework, or a computer code, that can automatically find tweaks that can be made to an existing autonomous system to achieve a desired outcome.

The heart of the code is based on automatic differentiation, or ‘autodiff’, a programming tool that was developed within the machine-learning community and was used initially to train neural networks. Autodiff can quickly and efficiently ‘evaluate the derivative’, or the sensitivity to change of any parameter in a computer program. Dawson and Fan built on recent advances in autodiff programming to develop a general-purpose optimisation tool for autonomous robotic systems.

‘Our method automatically tells us how to take small steps from an initial design toward a design that achieves our goals,’ Dawson said. ‘We use autodiff to essentially dig into the code that defines a simulator and figure out how to do this inversion automatically.’

The team tested their new tool on two separate autonomous robotic systems and showed that the it quickly improved each system’s performance in laboratory experiments, compared with conventional optimisation methods.

The first system comprised a wheeled robot tasked with planning a path between two obstacles, based on signals that it received from two beacons placed at separate locations. The team sought to find the optimal placement of the beacons that would yield a clear path between the obstacles. The new optimizer worked back through the robot’s simulation and identified the best placement of the beacons within five minutes, compared to 15 minutes for conventional methods.

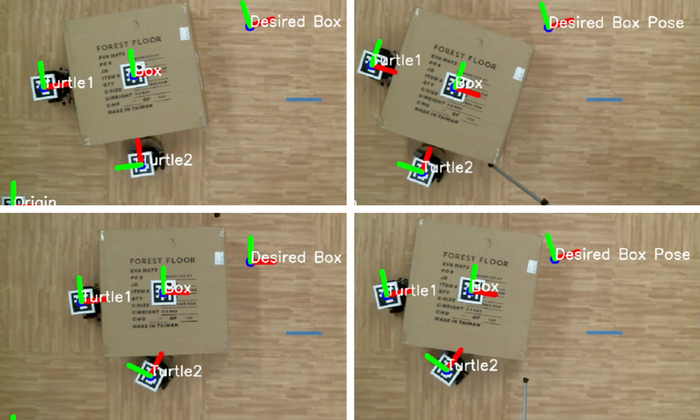

The second system was more complex, comprising two wheeled robots working together to push a box toward a target position. A simulation of this system included many more subsystems and parameters. Nevertheless, the team’s tool efficiently identified the steps needed for the robots to accomplish their goal 20 times faster than conventional approaches.

‘If your system has more parameters to optimise, our tool can do even better and can save exponentially more time,’ Fan said. ‘It’s basically a combinatorial choice – as the number of parameters increases, so do the choices, and our approach can reduce that in one shot.’

The team has made the general optimiser available to download and plans to further refine the code so that it will work with more complex systems, such as robots that are designed to interact with and work alongside humans.

‘Our goal is to empower people to build better robots,’ Dawson said. ‘We are providing a new building block for optimising their system, so they don’t have to start from scratch.’