A team of engineers at West Virginia University (WVU) has designed and successfully tested a fuel cell that can switch between storing or making electricity and also generate hydrogen from water. Unlike similar technologies, the fuel cell can withstand the heat and steam generated when running at an industrial scale for long periods at high power. Additionally, it addresses the three big problems with existing designs for a potentially valuable energy technology called a protonic ceramic electrochemical cell (PCEC).

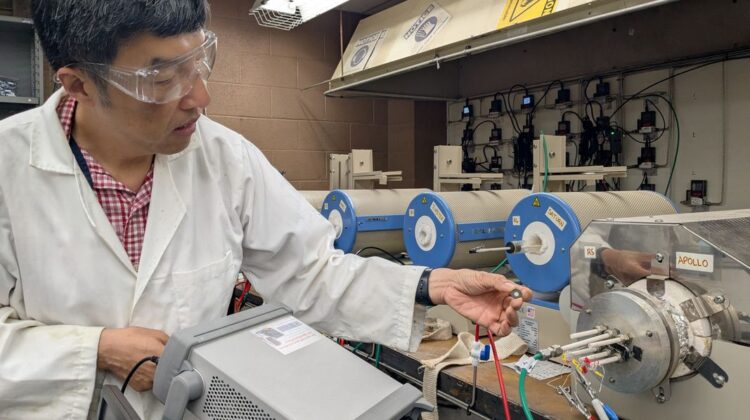

Researcher Xingbo Liu, a materials science professor and associate dean for research at the WVU Benjamin M Statler College of Engineering and Mineral Resources, explained that because PCECs switch between energy storage and power production, they could be a lifesaving technology for an overwhelmed US electrical grid struggling to incorporate the energy it receives at uncertain intervals from multiple sources – conventional power plants and hydropower dams as well as residential solar panels and even ocean waves.

However, according to Liu, current PCEC designs ‘are unstable in high steam environments, with weak connections between layers and they perform poorly at the critical task of conducting protons. In response, our group built a “conformally coated scaffold” design by connecting electrolytes, and we coated and sealed it with an electrocatalyst layer that’s stable in steam, absorbs water and stays intact as temperatures rise and fall. Protons, heat and electricity can all move through the structure.’

Their prototype did its job for more than 5,000 hours, at 600°C and 40 per cent humidity, breaking apart molecules to produce electricity and hydrogen through the process of electrolysis. The previous longest time a small PCEC continuously performed the same process was 1,833 hours – and in that case, performance degraded over time, Liu said.

‘That technology wasn’t ready for large-scale applications,’ he said. ‘By comparison, our conformally coated scaffold design (CCS) did so well in both energy storage and energy production modes that we also built a test version of a system that uses CCS cells to store hydrogen and use it in electrolysis reactions. Our system stayed stable while switching smoothly and frequently back and forth between those modes, even over 12-hour cycles. This is how we achieve balance in a power grid that’s evolving to incorporate intermittent, sustainable sources of energy.’

‘PCECs use membranes called electrolytes and conductors called oxygen electrodes to move protons through their layers,’ said Hanchen Tian, a WVU doctoral student and postdoctoral researcher. ‘But steam has been getting to the electrolytes in current PCEC designs and causing them to fail over time. Another problem is that the electrolytes and electrodes expand differently under heat, so the connections between them weaken during use.’

The WVU team incorporated the barium ion to help the coating hold water, which facilitates proton movement. They also incorporated nickel ions to manufacture larger CCS cells that stayed stable and flat. And because their PCEC runs on water vapour, it can be powered with saltwater or low-quality water, rather than purified water.

‘All that shows promise for scaling up to industrial levels,’ Tian said. ‘We showed that it’s possible to make, on a large scale, CCS fuel cells that will stay strong and stable under intense conditions.’

In the next phase of the project, the researchers will work with the WVU Office of Innovation and Commercialization to commercialise the design.

The research has been published in Nature Energy.