Researchers from MIT and the Institute of Science and Technology Austria have developed a computational technique that makes it easier for a user to quickly design a metamaterial cell from smaller building blocks and then evaluate the resulting metamaterial’s properties.

Engineers are constantly searching for materials with novel, desirable property combinations. For example, an ultra-strong, lightweight material could be used to make airplanes and cars more fuel-efficient, or a material that’s porous and biomechanically friendly could be useful for bone implants.

Cellular metamaterials – artificial structures composed of units, or cells, that repeat in various patterns – can help achieve these goals. But it’s difficult to know which cellular structure will lead to the desired properties. Even if one focuses on structures made of smaller building blocks such as interconnected beams or thin plates, there are an infinite number of possible arrangements to consider. So, engineers can manually explore only a small fraction of all the cellular metamaterials that are hypothetically possible.

The new approach, like a specialised CAD (computer-aided design) system for metamaterials, allows an engineer to quickly model even very complex metamaterials and experiment with designs that may have otherwise taken days to develop. The user-friendly interface also enables the user to explore the entire space of potential metamaterial shapes, since all of the possible building blocks are at their disposal.

‘We came up with a representation that can cover all of the different shapes engineers have traditionally shown interest in. Because you can build them all the same way, that means you can switch between them more fluidly,’ said MIT electrical engineering and computer science graduate student Liane Makatura.

When a scientist develops a cellular metamaterial, she typically begins by choosing a representation that will be used to describe her potential designs. This choice determines the set of shapes that will be available for exploration.

For instance, she may choose a technique that represents metamaterials using many interconnecting beams. However, this prevents her from exploring metamaterials based on other elements, such as thin plates or 3D structures such as spheres. Those shapes are given by different representations, but until now, there hasn’t been a unified way to describe all shapes in one method.

‘By choosing a specific subspace ahead of time, you limit your exploration and introduce a bias based on your intuition. While this can be useful, intuition can be incorrect, and some of the other shapes may have also been worth exploring for your particular application,” said Makatura.

She and her collaborators took a step back and closely examined different metamaterials. They saw that the shapes that comprise the overall structure could be easily represented by lower-dimensional shapes – a beam could be reduced to a line or a thin-shell could be compressed to a flat surface.

They also noticed that cellular metamaterials often have symmetries, so only a small part of the structure needs to be represented. The rest can be built by rotating and mirroring that initial piece.

‘By combining those two observations, we arrived at this idea that cellular metamaterials could be well represented as a graph structure,’ said Makatura.

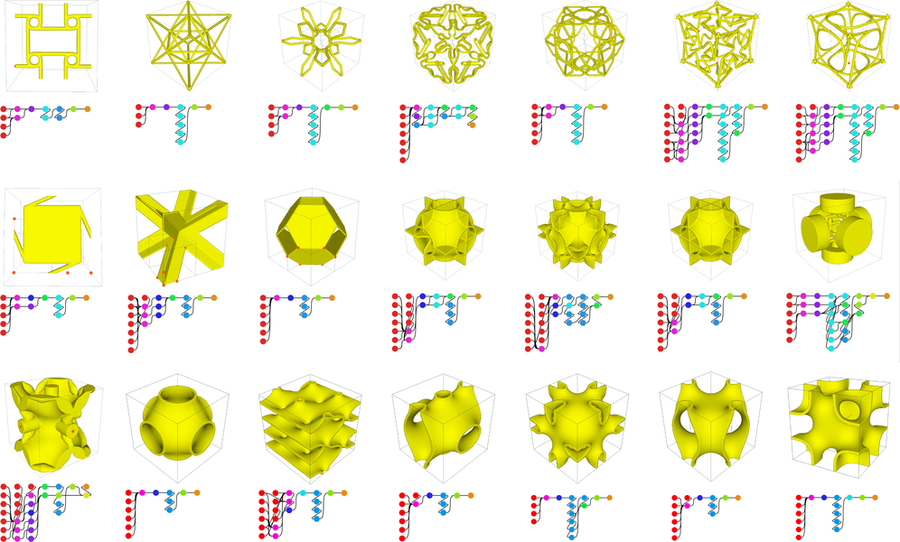

With the new graph-based representation, a user builds a metamaterial skeleton using building blocks that are created by vertices and edges. For instance, to create a beam structure, one places a vertex at each end point of the beam and connects them with a line.

The user then employs a function over that line to specify the thickness of the beam, which can be varied so one part of the beam is thicker than another.

The process for surfaces is similar – the user marks the most important features with vertices and then chooses a solver that infers the rest of the surface.

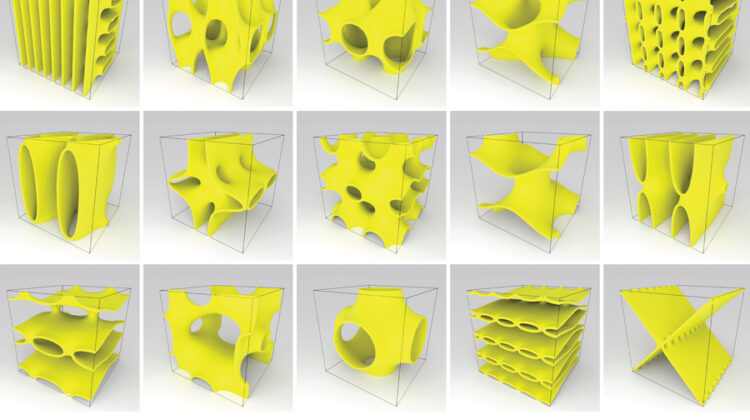

These easy-to-use solvers even allow users to quickly construct a highly complex type of metamaterial, called a triply periodic minimal surface (TPMS). These structures are incredibly powerful, but the process usually used to develop them is arduous and prone to failure.

‘With our representation, you can also start combining these shapes. Perhaps a unit cell containing both a TPMS structure and a beam structure could give you interesting properties. But so far, those combinations really haven’t been explored to any degree,’ said Makatura.

At the end of the process, the system outputs the entire graph-based procedure, showing every operation the user took to reach the final structure. Within the user interface, designers can preview the current structure at any point in the building procedure and directly predict certain properties, such as its stiffness. Then, the user can iteratively tweak some parameters and evaluate it again until a suitable design is reached.

The researchers used their system to recreate structures that spanned many unique classes of metamaterials. Once they had designed the skeletons, each metamaterial structure took only seconds to generate.

They also created automated exploration algorithms, giving each a set of rules and then turning it loose in their system. In one test, an algorithm returned more than 1,000 potential truss-based structures in about an hour.

In addition, the researchers conducted a user-study with ten individuals who had little prior experience modelling metamaterials. The users were able to successfully model all six structures they were given, and most agreed that the procedural graph representation made the process easier.

‘Our representation makes all sorts of structures more accessible to people. We were especially pleased with users’ ability to generate TPMS. These complex structures are usually difficult even for experts to generate. Still, one TPMS in our study had the lowest average modelling time out of all six structures, which was surprising and exciting,” said Makatura.

In the future, the researchers want to enhance their technique by incorporating more complex skeleton-thickening procedures, so the system can model a wider variety of shapes. They also want to continue exploring the use of automatic generation algorithms.

And in the long term, they would like to use this system for inverse design, where one would specify desired material properties and then use an algorithm to find the optimal metamaterial structure.