Researchers from the Singapore University of Technology and Design’s Bio-Inspired Robotics and Design Laboratory have developed a new reconfigurable workspace soft robotic gripper that can scoop, pick and grasp a wide range of consumer items. The gripper’s comprehensive and adaptive capabilities make it particularly suitable for the logistics and food industries, which increasingly depend on robotic automation to meet the demand for the efficient picking and packing of items.

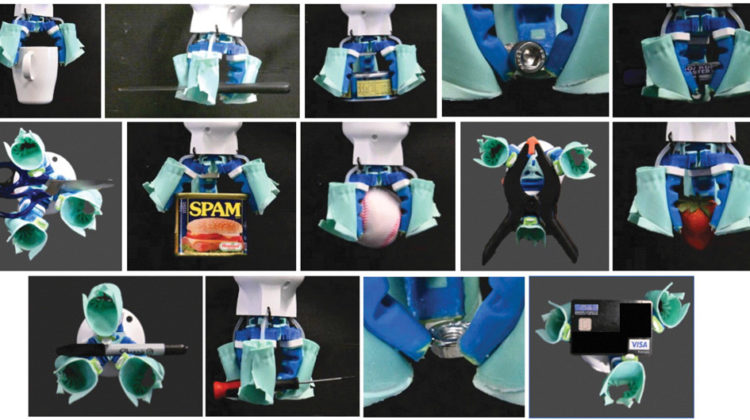

The gripper can reliably scoop up grains of rice or couscous with radii as small as 1.5 millimetres or pick items as thin as 300 microns, such as business cards or thin instruction manuals, from flat surfaces. It can also grasp large convex, nonconvex and deformable items such as melons, cereal boxes and detergent-refill bags that can weigh as much as 1.4 kilograms.

Compared to traditional rigid grippers, soft grippers use compliant soft actuators and functional hyper-elastic materials, allowing them to grasp a wider range of geometries safely and reliably. In addition, soft grippers’ high degrees of freedom and compliance enable several grasp modes, despite under actuation and oversimplified control strategies.

While they have advantages over their rigid counterparts, soft grippers’ capabilities are mostly a consequence of the gripper workspace, defined as the range of positions that a robot can reach to interact with its physical environment. This, in turn, is largely constrained by the gripper design. Moreover, soft grippers designed for highly specific grasping tasks such as scooping grains or wide payloads are usually limited in grasping other payload types or in their manipulation versatility.

To overcome these limitations, the research team designed the gripper using multimodal actuation, in which the grasping workspace of a soft gripper can be changed rapidly for payloads with different contact-area requirements.

The new gripper can modify and increase its grasping workspace volume by 397 per cent using a combination of shape-morphing fingers, retractable nails and an expandable palm, enabling the widest range of grasping capabilities ever achieved by a single soft gripper. Its ability to quickly reconfigure its grasping workspace makes it an ideal candidate for challenging applications for which multiple task-specific grippers would otherwise be required.

The research team is now taking steps to commercialise the grippers in a variety of high-mix automation applications. ‘We are in discussions with various logistics companies, both in the food and packaging sectors, to set up proof-of-value studies. The team is excited to create market impact and provide new solutions for our industry partners,’ said assistant Professor Pablo Valdivia y Alvarado, who led the research.

The research has been published in Soft Robotics.