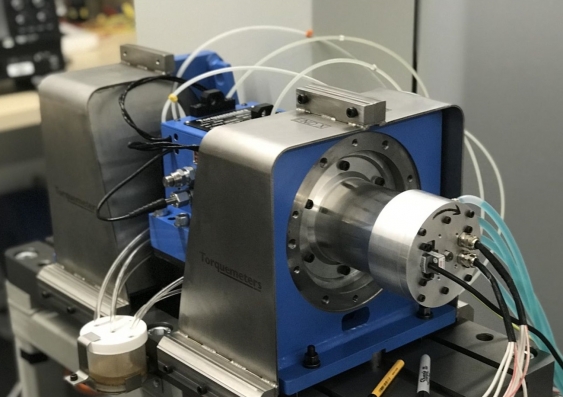

Engineers at the University of New South Wales have designed and built a new high-speed motor that has the potential to increase the range of electric vehicles. The design of the prototype Interior Permanent Magnet Synchronous Motor (IPMSM) was inspired by the shape of the longest railroad bridge in South Korea and has achieved speeds of 100,000 revolutions per minute.

The new motor is the fastest IPMSM ever built with commercialised lamination materials, having doubled the existing high-speed record of laminated IPMSMs. Most importantly, the motor is able to produce a very high power density, which potentially means a reduction in the weight of motors for EVs and hence an increased range for any given charge.

IPMSMs, which are predominantly used in traction drive of electric vehicles, have magnets embedded within their rotors to create strong torque for an extended speed range. However, existing IPMSMs suffer from low mechanical strength due to thin iron bridges in their rotors, which limits their maximum speed.

The UNSW team’s motor features a new rotor topology that significantly improves robustness, while also reducing the amount of rare earth materials per unit of power production. The new design is based on the engineering properties of the Gyopo rail bridge, a double-tied arch structure in South Korea, as well as a compound-curve-based mechanical stress distribution technique.

‘One of the trends for electric vehicles is for them to have motors which rotate at higher speeds,’ said Guoyu Chu from the UNSW School of Electrical Engineering and Telecommunications. ‘Every EV manufacturer is trying to develop high-speed motors and the reason is that the nature of the law of physics then allows you to shrink the size of that machine. And with a smaller machine, it weighs less and consumes less energy and therefore that gives the vehicle a longer range.

‘With this research project we have tried to achieve the absolute maximum speed, and we have recorded more than 100,000 revolutions per minute and the peak power density is around 7kW per kilogram,’ he continued. ‘For an electric vehicle motor we would actually reduce the speed somewhat, but that also increases its power. We can scale and optimise to provide power and speed in a given range – for example, a 200kW motor with a maximum speed of around 18,000 rpm that perfectly suits EV applications.

‘If an electric vehicle manufacturer such as Tesla wanted to use this motor, then I believe it would only take around six to 12 months to modify it based on their specifications,’ Chu concluded. ‘We have our own machine design software package where we can input the requirements of speed, or power density and run the system for a couple of weeks and it gives us the optimum design that satisfies those needs.’

The new IPMSM prototype was developed using the UNSW team’s AI-assisted optimisation program, which evaluated a series of designs for a range of different physical aspects – namely electrical, magnetic, mechanical and thermal. The program evaluates 90 potential designs before selecting the best 50 per cent of options to generate a new range of designs and so on until the optimum is achieved. The final motor was the 120th generation analysed by the program.

Apart from use in EVs, the motor has many other potential applications, including use in large heating, ventilation and air conditioning (HVAC) systems, which require high-speed compressors to use a new form of refrigerant that significantly reduces the impact on global warming.

The new motor also offers a significant cost advantage over existing technology.‘Most high-speed motors use a sleeve to strengthen the rotors and that sleeve is usually made of high-cost material such as titanium or carbon fibre. The sleeve itself is very expensive and also needs to be precisely fitted and that increases the manufacturing cost of the motor,’ said Chu. ‘Our rotors have very good mechanical robustness, so we don’t need that sleeve, which reduces the manufacturing cost. And we only use around 30 per cent of rare earth materials, which includes a big reduction in the material cost – thus making our high-performance motors more environmentally friendly and affordable.’