A team of MIT researchers has developed an open-source co-design platform that simulates wildlife, enabling soft robotics designers to test optimal shapes and sizes for robotic performance in different environments.

Since the term ‘soft robotics’ was adopted in 2008, engineers in the field have been building diverse representations of flexible machines useful in exploration, locomotion, rehabilitation and even space. One source of their inspiration has been the ways in which animals move in the wild.

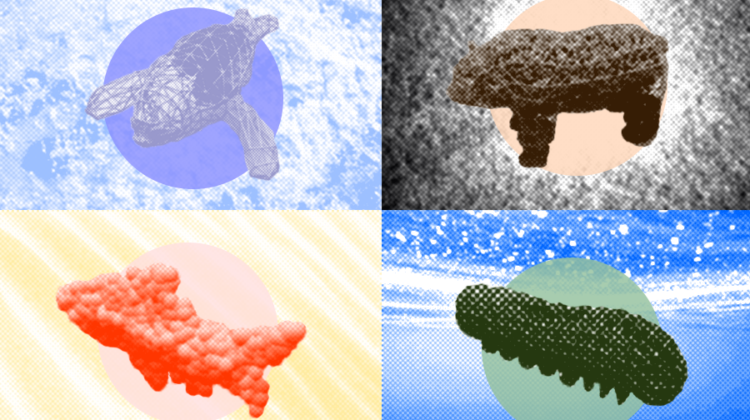

Dubbed SoftZoo, the platform features 3D models of animals such as pandas, fish, sharks and caterpillars as designs that can simulate soft robotics tasks such as locomotion, agile turning and path following in different environments. The platform then demonstrates the performance trade-offs of various designs in different terrains, including snow, desert, clay and water.

The framework optimises algorithms that consist of design, which determines what the robot will look like, and control – the system that enables robotic motion – improving how users automatically generate outlines for potential machines.

‘Our framework can help users find the best configuration for a robot’s shape, allowing them to design soft robotics algorithms that can do many different things,’ said MIT PhD student Tsun-Hsuan Wang, an affiliate of the Computer Science and Artificial Intelligence Laboratory (CSAIL). ‘In essence, it helps us understand the best strategies for robots to interact with their environments.’

SoftZoo is more comprehensive than similar platforms, which already simulate design and control, because it models movement that reacts to the physical features of various biomes. The framework’s versatility comes from a differentiable multi-physics engine that allows for the simulation of several aspects of a physical system at the same time, such as a baby seal turning on ice or a caterpillar inching across a wetland environment. The engine’s differentiability optimises co-design by reducing the number of the often-expensive simulations required to solve computational control and design problems. As a result, users can design and move soft robots with more sophisticated, specified algorithms.

The system’s ability to simulate interactions with different terrain illustrates the importance of morphology, a branch of biology that studies the shapes, sizes and forms of different organisms. Depending on the environment, some biological structures are more optimal than others, much like comparing blueprints for machines that complete similar tasks.

These biological outlines can inspire more specialised, terrain-specific artificial life. ‘A jellyfish’s gently undulating geometry allows it to efficiently travel across large bodies of water, inspiring researchers to develop new breeds of soft robots and opening up unlimited possibilities of what artificial creatures cultivated entirely in silico can be capable of,’ said Wang. ‘Additionally, dragonflies can perform very agile manoeuvres that other flying creatures cannot complete because they have special structures on their wings that change their centre of mass when they fly. Our platform optimises locomotion the same way a dragonfly is naturally more adept at working through its surroundings.’

Robots previously struggled to navigate through cluttered environments because their bodies were not compliant with their surroundings. With SoftZoo, however, designers could develop the robot’s brain and body simultaneously, co-optimising both terrestrial and aquatic machines to be more aware and specialised. With increased behavioural and morphological intelligence, the robots would then be more useful in completing rescue missions and conducting exploration. If a person went missing during a flood, for example, the robot could potentially traverse the waters more efficiently because it was optimised using methods demonstrated in the SotftZoo platform.

‘SoftZoo provides open-source simulation for soft robot designers, helping them build real-world robots much more easily and flexibly while accelerating the machines’ locomotion capabilities in diverse environments,’ said Chuang Gan, a research scientist at the MIT-IBM Watson AI Lab.

‘This computational approach to co-designing the soft robot bodies and their brains (that is, their controllers) opens the door to rapidly creating customised machines that are designed for a specific task,’ added Daniela Rus, director of CSAIL and the Andrew and Erna Viterbi professor in MIT’s Department of Electrical Engineering and Computer Science.

Before a robot is constructed, the framework could be a substitute for field testing unnatural scenes. For example, assessing how a bear-like robot behaves in a desert may be challenging for a research team working in the urban plains of Boston. Instead, soft robotics engineers could use 3D models in SoftZoo to simulate different designs and evaluate how effective the algorithms controlling their robots are at navigation, saving time and resources.

Still, the limitations of current fabrication techniques stand in the way of bringing these soft robot designs to life. ‘Transferring from simulation to physical robot remains unsolved and requires further study,’ said Wang. ‘The muscle models, spatially varying stiffness and sensorisation in SoftZoo cannot be straightforwardly realised with current fabrication techniques, so we are working on these challenges.’

The platform’s designers are now eyeing applications in human mechanics, such as manipulation, given its ability to test robotic control. To demonstrate this potential, Wang’s team designed a 3D arm that can throw a snowball. By including the simulation of more human-like tasks, soft robotics designers could then use the platform to assess soft robotic arms that grasp, move and stack objects.

Details of the research can be found here.