A team of engineers from Mercer University in Georgia, USA, has designed a novel polymeric material that can withstand extreme weathering conditions and is capable of self-healing.

The new material is a type of thermoplastic polymer. The researchers reinforced the polymer with various fillers, with the goal of creating unique properties that would improve the material.

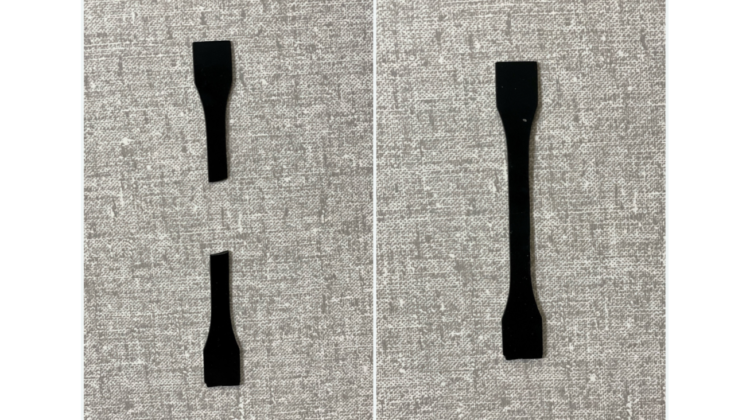

After preparing numerous samples, the researchers stretched, cut and heated them. Some of the samples were also put through an accelerated weathering machine prior to testing. Eventually, they identified a sample that demonstrated self-healing and weather-resistant capabilities.

‘We prepared a film of the material and broke it into two parts. We increased the temperature, and at 60°C or 70°C, it actually started healing,’ Sarvestani said. ‘Now we have a material whose property is almost exactly the same as before melting. By increasing the temperature locally, you can heal all the damage done. The other interesting property is that it’s very resistant to UV radiation.’

The material was only slightly weaker after healing. ‘It was just like magic. It re-healed, and the material was strong, almost just like before. The findings were just amazing,’ said Daniel Krashin, a student who worked on the project. ‘It was a very big discovery.’

According to Sarvestani, the material would be ideal for use as a coating, especially for aerospace and military vehicles. For example, pieces of an airplane could potentially be coated in the material to protect it from damage from debris in the air and UV exposure, or it could be used on ships to prevent corrosion. If damage or abrasion did occur, the material could be repaired simply by increasing the temperature.

The team is now planning to conduct further testing and begin to look at ways to improve other properties of the material, including mixing it with materials such as silver or gold in order to see if it will become conductive.