Taking inspiration from nature, researchers from Princeton Engineering have improved crack resistance in concrete components by coupling architected designs with additive manufacturing processes and industrial robots that can precisely control materials deposition. The designs increased resistance to cracking by as much as 63 per cent compared to conventional cast concrete.

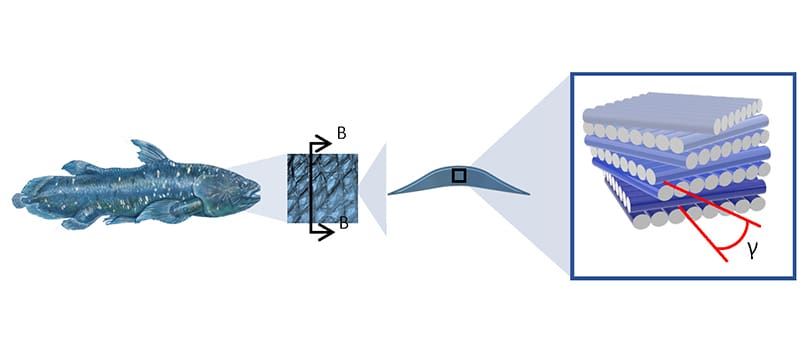

The team of researchers, led by Reza Moini, an assistant professor of civil and environmental engineering at Princeton, was inspired by the double-helical structures that make up the scales of an ancient fish lineage called coelacanths (see below). Moini said that nature often uses clever architecture to mutually increase material properties such as strength and fracture resistance.

To generate these mechanical properties, the researchers proposed a design that arranges concrete into individual strands in three dimensions. The design uses robotic additive manufacturing to weakly connect each strand to its neighbour. The researchers used different design schemes to combine many stacks of strands into larger functional shapes, such as beams. The design schemes rely on slightly changing the orientation of each stack to create a double-helical arrangement (two orthogonal layers twisted across the height) in the beams. This design is key to improving the material’s resistance to crack propagation.

The researchers refer to the underlying resistance in crack propagation as a ‘toughening mechanism’. The technique relies on a combination of mechanisms that can either shield cracks from propagating, interlock the fractured surfaces, or deflect cracks from a straight path once they are formed, Moini said.

Shashank Gupta, a graduate student at Princeton, said that creating architected concrete material with the necessary high geometric fidelity at scale in building components such as beams and columns sometimes requires the use of robots. This is because, currently, it can be very challenging to create purposeful internal arrangements of materials for structural applications without the automation and precision of robotic fabrication.

Additive manufacturing, in which material is added strand-by-strand to create structures, allows designers to explore complex architectures that aren’t possible with conventional casting methods. In Moini’s lab, researchers use large, industrial robots that are integrated with advanced real-time processing of materials. These robots are capable of creating full-sized structural components that are also aesthetically pleasing.

As part of the work, the researchers also developed a customised solution to address the tendency of fresh concrete to deform under its own weight. When a robot deposits concrete to form a structure, the weight of the upper layers can cause the concrete below to deform, compromising the geometric precision of the resulting architected structure. To address this, the researchers aimed to better control the concrete’s rate of hardening to prevent distortion during fabrication.

Gupta, who led the extrusion efforts of the study, explained that they used an advanced, two-component extrusion system implemented at the robot’s nozzle in the lab. The specialised robotic system has two inlets: one for concrete and another for a chemical accelerator. These materials are mixed within the nozzle just before extrusion, allowing the accelerator to expedite the concrete curing process while ensuring precise control over the structure and minimising deformation. By precisely calibrating the amount of accelerator, the researchers gained better control over the structure and minimised deformation in the lower levels.

The research has been published in Nature Communications.