A team of scientists from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed an innovative AI system that melds simulations and physical testing to forge materials with newfound durability and flexibility for a wide diversity of engineering uses.

The researchers moved beyond traditional trial-and-error methods to create materials with extraordinary performance through computational design. Their new system integrates physical experiments, physics-based simulations and neural networks to navigate the discrepancies often found between theoretical models and practical results. One of the most striking outcomes is the discovery of micro-structured composites – which are used in everything from cars to airplanes – that are much tougher and more durable than existing materials, with an optimal balance of stiffness and toughness.

‘Composite design and fabrication is fundamental to engineering,’ said Beichen Li, an MIT PhD student in electrical engineering and computer science. ‘The implications of our work will hopefully extend far beyond the realm of solid mechanics. Our methodology provides a blueprint for a computational design that can be adapted to diverse fields such as polymer chemistry, fluid dynamics, meteorology and even robotics.’

In the world of materials science, atoms and molecules are like tiny architects, constantly collaborating to build the future of everything. Still, each element must find its perfect partner, and in this case, the focus was on finding a balance between two critical properties of materials: stiffness and toughness. The team’s method involved a large design space of two types of base materials – one hard and brittle, the other soft and ductile – to explore various spatial arrangements to discover optimal microstructures.

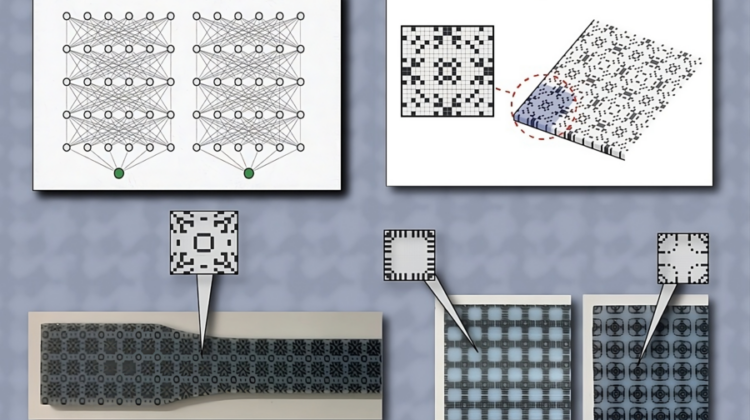

A key innovation in their approach was the use of neural networks as surrogate models for the simulations, reducing the time and resources needed for material design. ‘This evolutionary algorithm, accelerated by neural networks, guides our exploration, allowing us to find the best-performing samples efficiently,’ Li said.

The research team started its process by crafting 3D-printed photopolymers, roughly the size of a smartphone but slimmer, and adding a small notch and a triangular cut to each. After a specialised ultraviolet-light treatment, the samples were evaluated using a standard testing machine – the Instron 5984 – for tensile testing to gauge strength and flexibility.

The team melded these physical trials with sophisticated simulations. Using a high-performance computing framework, the team could predict and refine the material characteristics before creating them. The biggest feat, the fresearchers said, was in the nuanced technique of binding different materials at a microscopic scale – a method involving an intricate pattern of minuscule droplets that fused rigid and pliant substances, striking the right balance between strength and flexibility. The simulations closely matched physical testing results, validating the overall effectiveness.

Rounding the system out was the team’s Neural-Network Accelerated Multi-Objective Optimization (NMO) algorithm, which it used to navigate the complex design landscape of microstructures, unveiling configurations that exhibited near-optimal mechanical attributes. The workflow operates like a self-correcting mechanism, continually refining predictions to align closer with reality.

However, the journey wasn’t without challenges. Li highlighted the difficulties in maintaining consistency in 3D printing and integrating neural network predictions, simulations and real-world experiments into an efficient pipeline.

The team is now focused on making the process more usable and scalable. Li foresees a future where labs are fully automated, minimising human supervision and maximising efficiency. ‘Our goal is to see everything, from fabrication to testing and computation, automated in an integrated lab setup,’ Li concluded.

The research has been published in Science Advances.