Researchers at MIT and in Sweden have developed new kind of fibre that can be made into clothing that senses how much it’s being stretched or compressed, and then provides immediate tactile feedback in the form of pressure, lateral stretch or vibration. According to the researchers, such fabrics could be used in garments that help to train singers or athletes to better control their breathing, or that help patients recovering from disease or surgery to return their breathing patterns to normal.

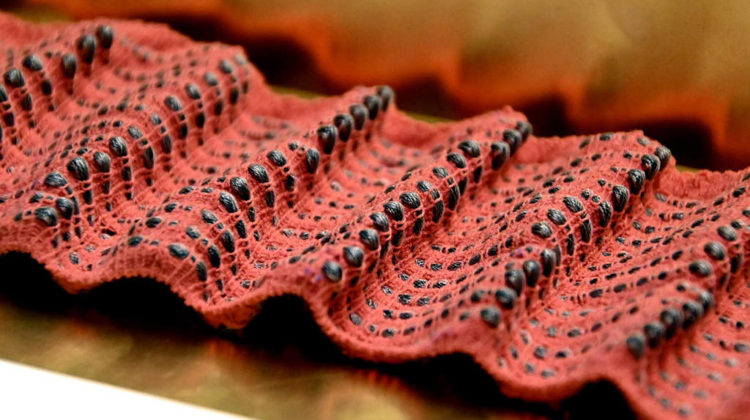

Dubbed OmniFibres, the multi-layered fibres, which resemble a strand of yarn,contain a fluid channel in the centre that can be activated by a fluidic system.Pressurising and releasing a fluid medium, such as compressed air or water, into the channel makes it possible to control the geometry of the fibres so that they can act as an artificial muscle. The composite fibres, which are thin and flexible enough to be sewn, woven or knitted using standard commercial machines, also contain sensors that can detect and measure the degree to which they are stretched.

Altogether, the soft fibre composite has five layers: the innermost fluid channel, a silicone-based elastomeric tube to contain the working fluid, a soft stretchable sensor that detects strain as a change in electrical resistance, a braided polymer stretchable outer mesh that controls the outer dimensions of the fibre and a non-stretchy filament that provides a mechanical constraint on the overall extensibility.

As an initial test application for the new material, the team incorporated it into a type of undergarment that singers can wear to monitor and play back the movement of respiratory muscles. The garment was then worn by a classically trained opera singer as she sang. The researchers recorded the movement data from the strain sensors woven into the garment and then translated the sensor data to the corresponding tactile feedback. ‘We eventually were able to achieve both the sensing and the modes of actuation that we wanted in the textile, to record and replay the complex movements that we could capture from an expert singer’s physiology and transpose it to a non-singer, a novice learner’s body,’ said Ozgun Kilic Afsar, a visiting doctoral student and research affiliate at MIT. ‘So, we are not just capturing this knowledge from an expert, but we are able to haptically transfer that to someone who is just learning.’

According to Afsar, the same approach could be used to help athletes to learn how best to control their breathing in a given situation, based on monitoring accomplished athletes as they carry out various activities and stimulating the muscle groups that are in action. Eventually, such garments could potentially also be used to help patients regain healthy breathing patterns after major surgery or a respiratory disease such as Covid-19, or even as an alternative treatment for sleep apnoea. Afsar is now working to further miniaturise the whole system, including its control electronics and compressed air supply, in order to make it as unobtrusive as possible, and to develop the manufacturing system so that it can produce longer filaments.