A team of researchers led by Professor Young Min Song from Gwangju Institute of Science and Technology in South Korea has developed a new flexible, lightweight and biodegradable thermoelectric generator (TEG) that was inspired by an unlikely source: zebra skin.

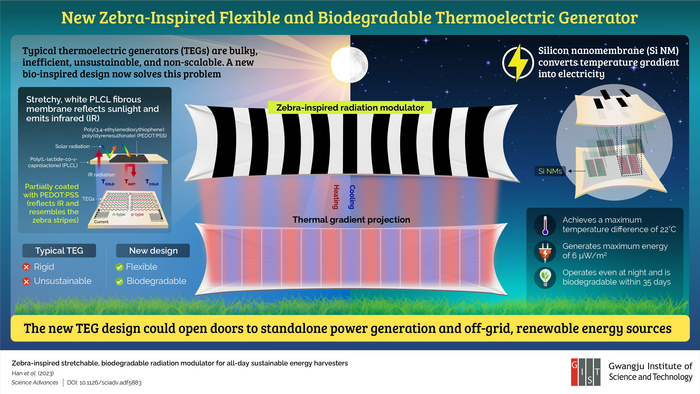

TEGs are devices that can convert temperature gradients to electricity. Such devices are extremely useful for generating electricity for remote sensors that can’t be connected to the main electricity grid. A conventional TEG is composed of one side that radiates heat to cool down and another side that absorbs heat from the sun or the environment. This, in turn, generates an out-of-plane temperature gradient that is converted into electricity. However, such requirements often make for designs that are bulky, complex and inefficient. This, in turn, makes TEGs difficult to integrate with other components or systems, limiting their applications in renewable-energy systems.

The researchers found a way potential way to surmount these challenges by designing a TEG that uses a pattern resembling black-and-white zebra stripes to create a high in-plane temperature gradient for generating electricity.

‘Traditional TEG designs are large and bulky as they rely on natural convection, which leads to an out-of-plane temperature gradient,’ said Professor Song. ‘This requires hard insulators, which limit the application of TEGs in flexible and wearable devices. We have now transcended this paradigm in our design by creating an in-plane device that is flexible and biodegradable. This increases its applicability while reducing its environmental impact by making it scalable, integrable and sustainable.’

‘This [breakthrough] is the result of research on the convergence of engineering and optics to realise flexible electronic devices, and it is significant that it succeeded in controlling the temperature in the horizontal direction, which was difficult to implement, and produced a power generation system with flexibility and elasticity,’ he continued.

The researchers manufactured their TEG using poly(L-lactide-co-ε-caprolactone) or PLCL, a white, flexible and biodegradable material that reflects sunlight and emits infrared radiation, which allowed the area below it to be cool. On top of this material, the researchers applied black poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) or PEDOT:PSS, which appears black to the eye because it absorbs the sunlight that falls it. The material also reflects the infrared radiation that is coming from below it (emitted by the PLCL). This, in turn, increases the temperature of the area below the black stripes, creating alternating warm and cold regions – that is, a temperature gradient – which can then be converted into electricity.

The researchers achieved this conversion incorporating an array of silicon nanomembranes in their design. The novel design was able to generate a maximum temperature difference of 22°C, along with a maximum energy density of 6 µW/m². The power generation performance was maintained even when the square-shaped film was pulled from the four corners and stretched about 1.3 times. Moreover, the device was completely biodegraded without any remaining by-products within just 35 days.

With these remarkable properties, the new TEG design is sure to open doors to scalable, eco-friendly energy systems. ‘[There is a clear] need for sustainable and eco-friendly solutions such as TEGs that can be incorporated into wearable devices for performing specialised functions such as self-power generation and sensing,’ said Professor Song. ‘Our design can fill in this gap thanks to its lightweight and biodegradable nature. It can also be integrated seamlessly into various energy- and smart-grid technologies to further enhance their functionality and impact.’

The research has been published in Science Advances.