A team of University of Alberta engineering researchers is investigating the design and manufacturing of advanced materials for small modular nuclear reactors using 3D printing.

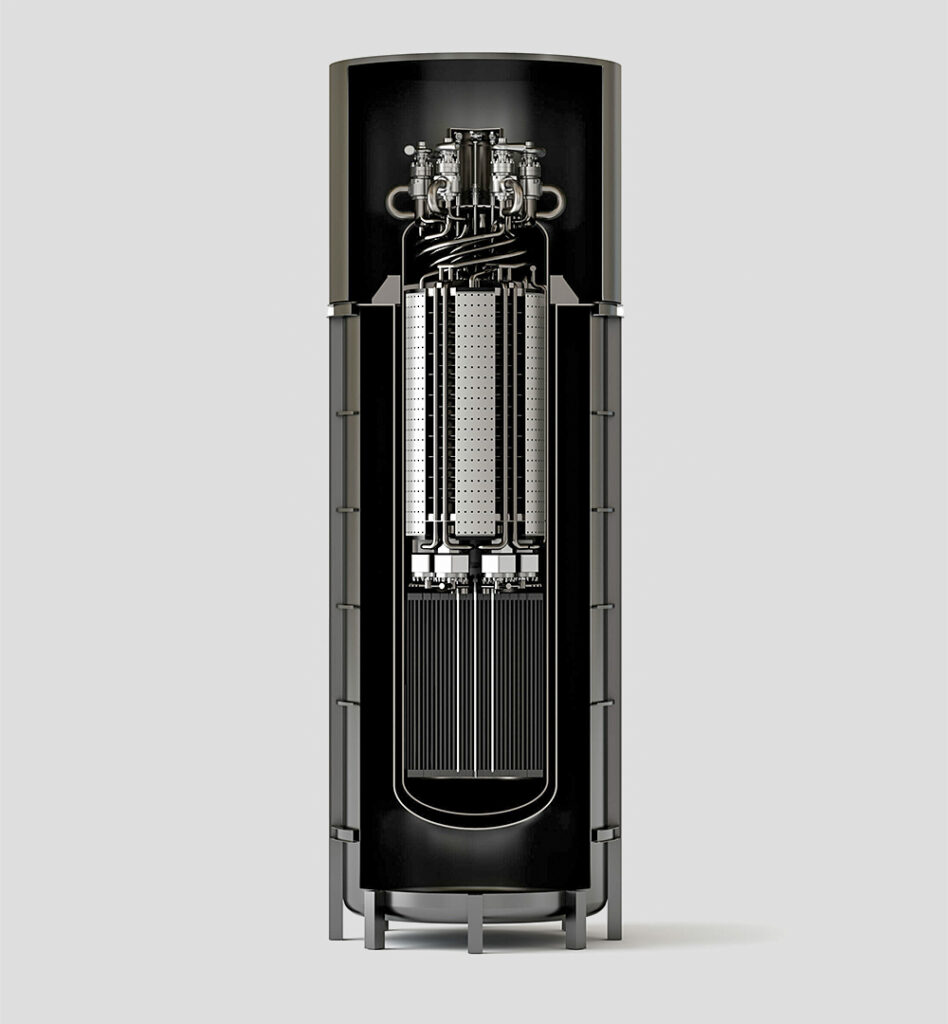

Small modular reactors (SMRs) can generate enough power to run an industrial plant or cover the energy needs of a small rural community. At a fraction of the size of a conventional nuclear power reactor – weighing between 200 and 500 tonnes and with a capacity of up to 300 megawatts – their modules can be manufactured in a factory and later transported to the site for final assembly and installation, leading to increased efficiency and improved return on investment.

According to the International Atomic Energy Agency, these fission reactors can be installed in rural locations that aren’t suitable for larger nuclear plants. More than 80 designs have been developed in the USA, Argentina, China, Russia, South Korea and Canada – all inching towards regulatory approval sometime this decade.

Mostafa Yakout, a mechanical engineering professor at the University of Alberta, recently received CA$2.5million over the next three years from Natural Resources Canada’s Enabling Small Modular Reactors Program and related programmes and industry partnerships to develop and test advanced materials for use in Canadian-made, high-performance SMRs that operate at high temperatures.

‘This is a critical part of Alberta’s energy future,’ said Yakout. ‘Nuclear is considered one of the cleanest types of energy, and Alberta is well positioned to lead the SMR effort in Canada, if not in North America.’ About a dozen doctoral students and postdoctoral fellows will also work on the project.

The research team will explore ways to make the containment material inside the fission reactors – which must hold up under temperatures as high as 850°C – less corrosive and more durable, while making manufacturing cheaper with less waste. They will begin by attempting to modify a superalloy used in conventional nuclear reactors, called Inconel 617, used to resist corrosion under extreme heat.

‘We’re looking for ways to prevent materials degradation to increase the operational life of reactor components and reduce the refuelling intervals,’ said Yakout. ‘High-temperature, corrosion-resistant materials will operate under extreme thermal-stress conditions, which will add passive safety features to prevent accidents or leaks in reactors. [Using 3D printing], we are able to integrate design materials and manufacturing to make very complex structures.’

To make the product commercially viable, the team is also exploring applications in other sectors such as defence, space and aerospace. Working with industry and government partners, Yakout’s team is aiming for a high-performance standard in its materials design that will stand up to regulatory approval once the reactors are ready for deployment. ‘We want to be sure that when the reactors are ready to go, we have all the regulations and licensing in place, and that the public is satisfied they are safe and clean,’ he said.