A team of researchers at MIT has developed a new way of 3D printing mechanisms that can detect how force is being applied to an object.

The new technique involves integrating electrodes into structures made from metamaterials –materials that are divided into a grid of repeating cells – and will allow designers to 3D print ‘interactive input devices’ such as joysticks, switches or handheld controllers in one go.

‘Metamaterials can support different mechanical functionalities,’ said one of the study’s lead authors, Jun Gong, a former visiting PhD student at MIT who is now a research scientist at Apple. ‘But if we create a metamaterial door handle, can we also know that the door handle is being rotated, and if so, by how many degrees? If you have special sensing requirements, our work enables you to customise a mechanism to meet your needs.’

‘What I find most exciting about the project is the capability to integrate sensing directly into the material structure of objects. This will enable new intelligent environments in which our objects can sense each interaction with them,’ said Associate Professor Stefanie Mueller, who also worked on the project. ‘For instance, a chair or couch made from our smart material could detect the user’s body when the user sits on it and either use it to query particular functions (such as turning on the light or TV) or to collect data for later analysis (such as detecting and correcting body posture).’

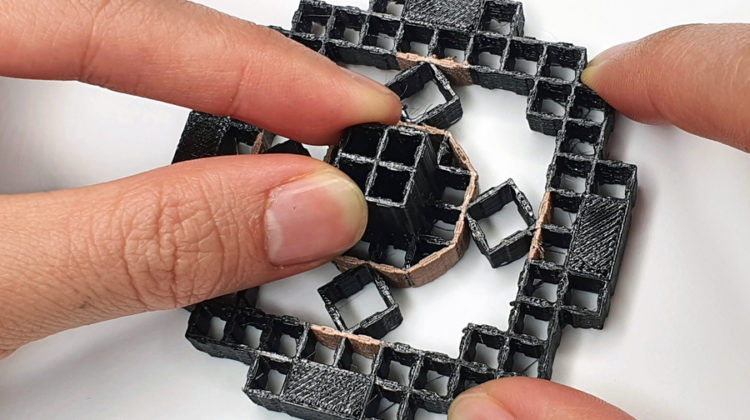

Metamaterials are made from a grid of cells, so when force is applied to a metamaterial object, some of the flexible, interior cells stretch or compress. The researchers created flexible cells with opposing walls made from conductive filament, which function as electrodes, and two walls made from nonconductive filament. When force is applied to the metamaterial, these so-called ‘conductive shear cells’ stretch or compress, causing the distance and overlapping area between the opposing electrodes to change.By using capacitive sensing, those changes can be measured and used to calculate the magnitude, acceleration and direction of the force being applied.

To demonstrate the new technique, the researchers built a metamaterial joystick with four conductive shear cells embedded around the base of the handle and used it to play Pac-Man.

The team also created 3D editing software, which they dubbed MetaSense,that simplifies the process of building such devices. Users can choose to either manually integrate sensing into a metamaterial design or let the software automatically place the conductive shear cells in optimal locations.

‘The tool will simulate how the object will be deformed when different forces are applied, and then use this simulated deformation to calculate which cells have the maximum distance change. The cells that change the most are the optimal candidates to be conductive shear cells,’ said Gong.

Although the researchers tried to make MetaSense straightforward to use, printing such complex structures brings a number of challenges. ‘In a multi-material 3D printer, one nozzle would be used for nonconductive filament and one nozzle would be used for conductive filament, but it is quite tricky because the two materials may have very different properties,’ Gong continued. ‘It requires a lot of parameter-tuning to settle on the ideal speed, temperature and so on. But we believe that, as 3D-printing technology continues to get better, this will be much easier for users in the future.’