Siemens has released a new version of its NX software that features a number of advanced technologies, including artificial intelligence and advanced simulation capabilities.

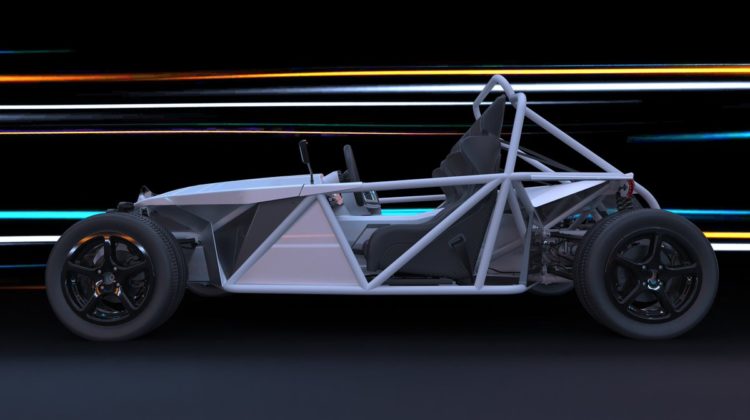

Among the new features added to the latest release of NX are the new NX Topology Optimizer, which can be used to design parts based purely based on functional and design space requirements, resulting in fully editable convergent bodies that, according to the company, would be almost impossible to design and engineer manually. The inevitable changes to designs can be made quickly and optimisations and downstream features updated automatically, saving time and effort, and maximising the reuse of design and engineering data.

The Design Space Explorer combines design space exploration with generative engineering to help designers automatically optimise a design against multiple objectives. Design engineers can define the optimisation problem with all of the parameters, constraints and objectives in place and then use to conduct multi-objective parameter optimisation, providing the designer with a set of viable design alternatives to consider.

‘In the latest revision of NX, Siemens Digital Industries Software has smoothly woven topology optimisation design from requirements through to component generation, additive manufacturing and final machining by leveraging its convergent modelling and automated model-based definition authoring for PMI generation, together with task-based collaboration,’ said Ken Versprille, an executive Consultant at strategic management consulting firm CIMdata. ‘Users will welcome the effortless user interface, which guides stakeholders through each step of the process.’

‘With each new release of NX, Siemens is pushing the barriers of what product development systems are capable of,” said Bob Haubrock, senior vice president product engineering software, Siemens Digital Industries Software. ‘Our shift to continuous releases of NX is proving incredibly popular with our community – enabling us to deliver industry-leading capabilities more quickly than before. This means providing access to new tools and technologies so they can be applied to our customers’ design, engineering and manufacturing challenges to help them overcome them more quickly. We continue to improve the core tools our customers rely on every day, with more than 1,200 customer-enhancement requests delivered in this release.’