A research team at the Hebrew University of Jerusalem has described a method for 3D printing flat wooden shapes that self-morph into complex 3D shapes as they dry. The research could potentially pave the way for the design of furniture or other wooden products that could be shipped flat to a destination and then dried to form the desired final shape.

Even after a tree is cut down, its wood can change shape as it dries. It shrinks unevenly and warps because of variations in fibre orientation within the wood. ‘Warping can be an obstacle,’ said Doron Kam, a Hebrew University graduate student, ‘but we thought we could try to understand this phenomenon and harness it into a desirable morphing.’

Artificial structures can’t typically shape themselves, said Eran Sharon, one of the project’s principal investigators, but in recent years, scientists have begun printing flat sheets that can form themselves into 3D shapes after a stimulus, such as a change in temperature, pH or moisture content. However, these self-morphing sheets were made from synthetic materials, such as gels and elastomers. ‘We wanted to go back to the origin of this concept, to nature, and do it with wood,’ Sharon said.

A few years ago, the team developed an environmentally friendly water-based ink composed of wood-waste microparticles known as ‘wood flour’ mixed with cellulose nanocrystals and xyloglucan, which are natural binders extracted from plants. The researchers then began to use the ink in a 3D printer. They recently discovered that the way the ink is laid down, or the ‘pathway,’ dictates the morphing behaviour as the moisture content evaporates from the printed piece. For instance, a flat disk printed as a series of concentric circles dries and shrinks to form a saddle-like structure reminiscent of a Pringles potato chip, and a disk printed as a series of rays emanating from a central point turns into a dome or cone-like structure.

The ultimate shape of the object can also be controlled by adjusting print speed, the team found, because shrinkage occurs perpendicular to the wood fibres in the ink and print speed changes the degree of alignment of those fibres. A slower rate leaves the particles more randomly oriented, so shrinkage occurs in all directions; faster printing aligns the fibres with one another, so shrinkage is more directional.

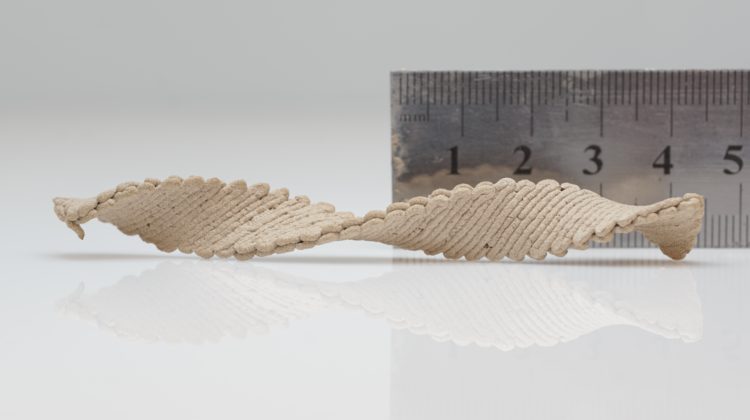

The scientists learned how to programme the print speed and pathway to achieve a variety of final shapes. They found that stacking two rectangular layers that are printed in different orientations yields a helix after drying. In their latest work, they found that they can programme the printing pathway, speed and stacking to control the specific direction of shape change, such as whether rectangles twist into a helix that spirals clockwise or counter-clockwise.

Further refinement will allow the team to combine the saddles, domes, helices and other design motifs to produce objects with complicated final shapes, such as a chair. Ultimately, it could be possible to make wood products that are shipped flat to the end user, which could reduce shipping volume and costs, Kam said. ‘Then, at the destination, the object could warp into the structure you want.’ Eventually, it might be feasible to license the technology for home use so consumers could design and print their own wooden objects with a regular 3D printer, Sharon said.

The team is also exploring whether the morphing process could be made reversible. ‘We hope to show that under some conditions, we can make these elements responsive – to humidity, for example – when we want to change the shape of an object again,’ Sharon said.