A team of engineers from MIT and the US National Renewable Energy Laboratory have designed a heat engine with no moving parts that can convert heat to electricity with better than 40 per cent efficiency – a performance better than that of traditional steam turbines.

The heat engine is a thermophotovoltaic (TPV) cell, similar to a solar panel’s photovoltaic cells, that passively captures high-energy photons from a white-hot heat source and converts them into electricity. The team’s design can generate electricity from a heat source with a temperature of between 1,900°C and 2,400°C.

The researchers plan to incorporate the TPV cell into a grid-scale thermal battery. The system would absorb excess energy from renewable sources such as the sun and store it in heavily insulated banks of hot graphite. When the energy is needed, such as on overcast days, the TPV cells would convert the heat into electricity and dispatch it to a power grid.

The team has now successfully demonstrated the main parts of the system in separate, small-scale experiments and is now working to integrate the parts into a fully operational system. From there, they hope to scale up the system to replace fossil-fuel-driven power plants, enabling the creation of a fully decarbonised power grid.

‘Thermophotovoltaic cells were the last key step toward demonstrating that thermal batteries are a viable concept,’ said Asegun Henry, the Robert N Noyce career development professor in MIT’s Department of Mechanical Engineering. ‘This is an absolutely critical step on the path to proliferate renewable energy and get to a fully decarbonised grid.’

More than 90 per cent of the world’s electricity comes from heat sources such as coal, natural gas, nuclear energy and concentrated solar energy. For a century, steam turbines have been the industrial standard for converting such heat sources into electricity.

On average, steam turbines reliably convert about 35 per cent of their source hear into electricity; the highest efficiency ever achieved is about 60 per cent. However, the machinery depends on moving parts that are temperature-limited, ruling out heat sources higher than 2,000°C.

Recently, scientists have begun to investigate solid-state alternatives – heat engines with no moving parts – that could potentially work efficiently at higher temperatures. ‘One of the advantages of solid-state energy converters is that they can operate at higher temperatures with lower maintenance costs because they have no moving parts,’ Henry said. ‘They just sit there and reliably generate electricity.’

Thermophotovoltaic cells offer one potential route to the creation of solid-state heat engines. Much like solar cells, TPV cells can be made using semiconducting materials with a particular bandgap – the gap between a material’s valence band and its conduction band. If a photon with a high enough energy is absorbed by the material, it can kick an electron across the bandgap, where the electron can then conduct, and thereby generate, electricity – without using rotors or blades.

To date, most TPV cells have reached efficiencies of only around 20 per cent; the record is 32 per cent. In the new TPV design, the team used multiple layers of higher-bandgap materials to capture higher-energy photons from a higher-temperature heat source, thereby converting energy more efficiently.

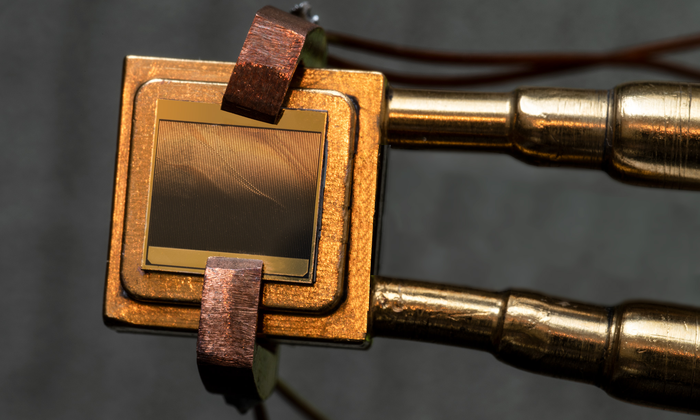

The cell consists of a high-bandgap alloy that sits over a slightly lower-bandgap alloy, underneath which is a mirror-like layer of gold. The first layer captures the heat source’s highest-energy photons and converts them into electricity. Lower-energy photons that pass through the first layer are captured by the second. Any photons that pass through this second layer are then reflected back to the heat source by the mirror, rather than being absorbed as waste heat.

The prototype cell has an area of about one square centimetre. For a grid-scale thermal battery system, Henry envisions TPV cells with an area of about 930 square metres. They would operate in climate-controlled warehouses, drawing power from huge banks of stored solar energy. He pointed out that the infrastructure for making large-scale photovoltaic cells, which could also be adapted to manufacture TPVs, already exists.

‘There’s definitely a huge net positive here in terms of sustainability,’ Henry said. ‘The technology is safe, environmentally benign in its life cycle, and can have a tremendous impact on abating carbon dioxide emissions from electricity production.’

The research has been published in Nature.