A miniaturised surgical robot developed by engineers at the University of Nebraska-Lincoln is set to blast off into space to showcase its skills aboard the International Space Station.

‘NASA has been a long-term supporter of this research and, as a culmination of that effort, our robot will have a chance to fly on the International Space Station,’ said Shane Farritor, the David and Nancy Lederer professor of engineering at the University of Nebraska-Lincoln.

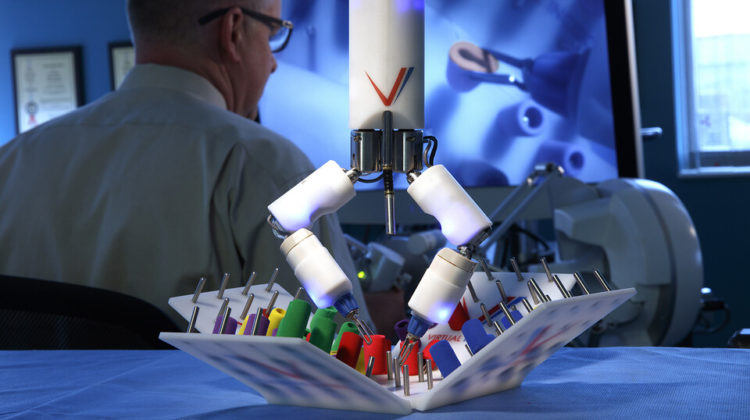

Farritor is co-founder of Virtual Incision, a start-up company based on Nebraska Innovation Campus. For nearly 20 years, he and his colleagues have been developing a tiny surgical robot known as MIRA, short for ‘miniaturised in vivo robotic assistant’.

During the next year, Farritor and engineering graduate student Rachael Wagner will write software, configure MIRA to fit inside a space station experiment locker and exhaustively test the device to make sure that it’s robust enough to survive launch and that its systems will perform as anticipated in space. Then, they will wait a year or so for the robot to get its turn aboard the station.

MIRA has two key advantages. First, it can be inserted through a small incision, enabling doctors to perform abdominal surgery in a minimally invasive manner. In previous tests, surgeons have successfully used the device to perform colon resections.

Second, the technology could allow surgeons to work remotely – perhaps someday repairing an astronaut’s ruptured appendix on a mission to Mars or removing shrapnel from a soldier injured by an improvised explosive device from thousands of kilometres away.

In a previous experiment, retired NASA astronaut Clayton Anderson took the robot’s controls while at the Johnson Space Center in Houston, directing MIRA to perform surgery-like tasks in an operating room 1,450 kilometres away at the University of Nebraska Medical Center in Omaha.

During its upcoming trip aboard the space station, MIRA will work autonomously, without the guiding hand of a doctor or an astronaut. Inside a microwave-oven-sized experiment locker, it will cut tautly stretched rubber bands and push metal rings along a wire – gestures that simulate those used in surgery.

‘These simulations are very important because of all of the data we will collect during the tests,’ Wagner said.

It will be the most autonomous operation of the robot so far. Although Farritor anticipates that MIRA will function on its own in 50–100 years, this mission’s goal isn’t autonomy, but rather to fine-tune the robot’s operation in zero gravity.

The device is being programmed to work autonomously to conserve space station communications bandwidth and to minimise the amount of time astronauts spend with the experiment.

‘The astronaut flips a switch, the process starts and the robot does its work by itself,’ Farritor said. ‘Two hours later, the astronaut switches it off and it’s done.

‘As people go further and deeper into space, they might need to do surgery someday,’ he continued. ‘We’re working toward that goal.’