Researchers at North Carolina State University have created a ring-shaped soft robot capable of crawling across surfaces when exposed to elevated temperatures or infrared light. The researchers have demonstrated that these ‘ringbots’ are capable of pulling a small payload across the surface – in ambient air or underwater – as well as passing through a gap that’s narrower than their ring size.

The ringbots are made of liquid crystal elastomers in the shape of looped ribbon, resembling a bracelet. When a ringbot is placed on a surface that’s at least 55°C, the portion of the ribbon touching the surface contracts, while the portion of the ribbon exposed to the air doesn’t. This induces a rolling motion in the ribbon.

Similarly, when infrared light is shined on the ringbot, the portion of the ribbon exposed to the light contracts, while the portion shielded from the light doesn’t. This also induces a rolling motion in the ribbon. In practical terms, this means that the crawling ringbot moves from the bottom up when placed on a hot surface, but when exposed to infrared light, the movement begins from the top down.

One of the things that drives this continuous motion is the fact that the ringbots are bistable, meaning that there are two shapes when it’s at rest. If the ribbon begins to twist, it will either snap back to its original shape, or snap forward into the other bistable state.

Picture a rubber bracelet shaped like a ribbon. If you fold two ends of the bracelet forward a little bit, then let go, it will snap back to its original shape. But if you fold the ends over far enough, it will snap over – essentially folding the bracelet inside out.

In the case of the ringbots, the ‘folding’ is done by applying constant heat or infrared light, causing the elastomer to contract and rotate. If the ring robot is symmetrical, this will essentially make it dance in place.

‘But by engineering the shape of the loop, so that one side of the loop is permanently twisted, the structure is asymmetrical,’ said Jie Yin, an associate professor of mechanical and aerospace engineering at NC State. ‘This means that the loop is exposed to the heat or infrared light unevenly, which causes the soft robot to move laterally across the surface.’

When placed on a hot surface, the end result is that the crawling ringbot pulls itself forward, but when exposed to infrared light, the crawling ringbot pushes itself forward – a bit like front-wheel drive versus rear-wheel drive.

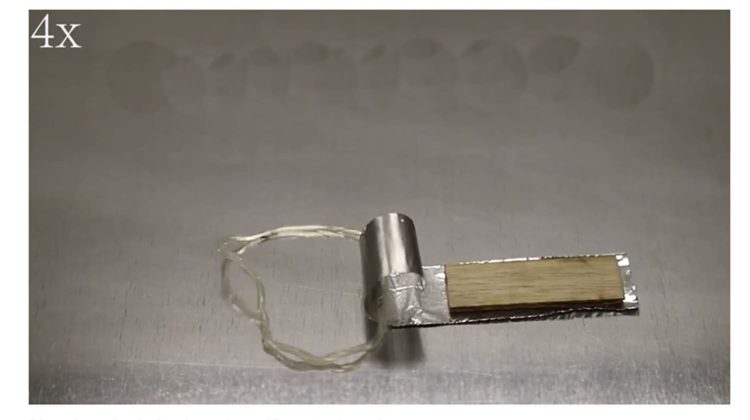

In demonstrations, the ringbots were capable of pulling a small payload and worked both in ambient air and underwater. The researchers also demonstrated that a ringbot could adapt its body shape to squeeze through a confined space that’s more than 30 per cent narrower than the ringbot’s diameter. And when the gap is too narrow for the soft robot to pass through, it redirects itself to move away from the gap.

‘This is a fundamental advance, not something designed with a specific application in mind,’ said Yao Zhao, a postdoctoral researcher in Yin’s lab. ‘We are demonstrating what can be accomplished when “physical intelligence” is engineered into the material and the design of the structure itself, allowing it to move and navigate space without computational input.’

The research has been published in Advanced Materials.