A team of researchers at the University of Illinois at Urbana-Champaign has revolutionised the design of heat exchangers using topology optimisation and metal 3D printing.

Heat exchangers are used in most major industries – including energy, water, manufacturing, transportation, construction, electronic, chemical, petrochemical, agriculture and aerospace –to transfer thermal energy from one medium to another. Their design has remained relatively unchanged for decades, but recent advancements in 3D printing have allowed the production of new designs that were previously thought to be impossible.

More compact and efficient heat exchangers can reduce fossil fuel use. And with billions of heat exchangers in use worldwide today, there is significant demand for better-designed examples.

Now, researchers at the Grainger College of Engineering have developed new software tools that enable the creation of innovative 3D heat-exchanger designs using metal 3D printing. ‘We developed shape-optimisation software to design a high-performance heat exchanger,’ said one of the study’s lead researchers, William King, professor of mechanical science and engineering at the Grainger College of Engineering. ‘The software allows us to identity 3D designs that are significantly different and better than conventional designs.’

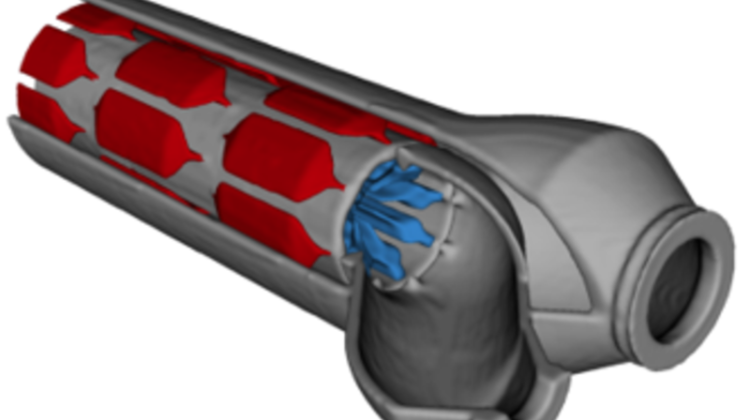

The team started by studying a tube-in-tube heat exchanger, a design commonly used in drinking water and building energy systems in which a tube is nested inside another tube.They then used a combination of the new shape-optimisation software and additive manufacturing to design and build fins internal to the tubes. According to the researchers, building the fins was only made possible through the use of metal 3D printing.

‘We designed, fabricated and tested an optimised tube-in-tube heat exchanger,’ said another of the study’s lead researchers, Nenad Miljkovic, associate professor of mechanical science and engineering. ‘Our optimised heat exchanger has about 20 times higher volumetric power density than a current state-of-the-art commercial tube-in-tube device.’

The research has been published in the journal Joule.