Eureka Robotics, a tech spin-off from Nanyang Technological University (NTU), Singapore, has upgraded its force-feedback Dynamis software technology for industrial robots to give it improved touch sensitivity and precision. The engineers behind the software say that it makes industrial robots almost as sensitive as human hands.

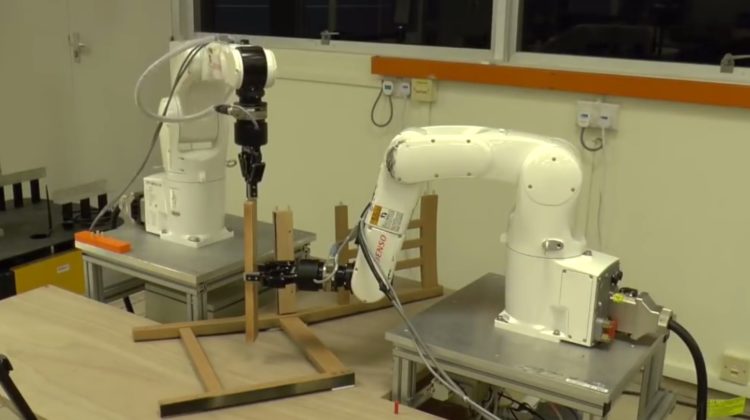

Dynamis is a complex artificial intelligence algorithm first deployed in Eureka’s custom-built robots, such as Archimedes, which can handle fragile optical lenses and mirrors with human-like dexterity. In 2018, NTU scientists demonstrated the technology using the ‘Ikea Bot’, which assembled an Ikea flat-pack chair in less than 20 minutes.

Conferring touch sensitivity and dexterity akin to that of human hands has long represented the Holy Grail for roboticists; however, the programming of force controllers is extremely complicated, requiring long hours to perfect the grip just for a single, specific task. The new software, known as ‘Force Sensor Robust Compliance Control’, requires only a single parameter – the stiffness of the contact, whether soft, medium or hard – to be set.

‘Today, Dynamis has made it easy for anyone to programme touch-sensitive tasks that are usually done by humans, such as assembly, fine manipulation, polishing or sanding,’ said Associate Professor Pham Quang Cuong, co-founder of Eureka Robotics and deputy director of the Robotics Research Centre at NTU’s School of Mechanical and Aerospace Engineering. ‘These tasks all share a common characteristic: the ability to maintain consistent contact with a surface. If our human hands are deprived of our touch sensitivity, such as when wearing a thick glove, we would find it very hard to put tiny Lego blocks together, much less assemble the tiny components of a car engine or of a camera used in our mobile phones.’

The software technology will be made available as an option for companies that purchase industrial robots made by Denso Wave, which is part of the Toyota Group. It will form part of the force controller, which reads the force detected by a force sensor on the robot’s wrist and applies force accordingly.

The new technology paves the way for industrial applications that were previously very difficult or impossible to implement, such as the handling and assembly of delicate, fragile objects such as optical lenses, electronics components and engine gears. Denso Wave robots equipped with Dynamis are capable of precisely assembling gears eight times faster than conventional industrial robots, signalling a huge potential for improvements in productivity.