A team of chemists and engineers at Georgia Institute of Technology has designed a transparent polymer film that conducts electricity as effectively as other commonly used materials, while also being flexible and easy to use at an industrial scale.

Their initial plan for creating the new material was to simply remove the nonconductive material from their conductive element. The resulting process could yield new kinds of flexible, transparent electronic devices, such as wearable biosensors, organic photovoltaic cells and virtual- or augmented-reality displays and glasses.

‘We had this initial idea that we have a conductive element that we’re covering with a non-conductive material, so what if we just get rid of that,’ said James Ponder, a mechanical engineering research scientist. ‘It’s a simple idea and there were so many points where it could have failed for different reasons, but it does work and it works better than we expected.’

To make a plastic film that can carry an electric charge, chemists typically start with a known polymer backbone – in this case, a popular polymer known as PEDOT. It conducts electricity effectively but is difficult to use in its bare form because it’s insoluble. However, when side chains are added to the PEDOT, it can be dissolved and used as a printable ink or a spray paint, which makes it easy to use and apply. Unfortunately, the side chains are essentially a waxy material and wax is a poor conductor.

‘If you think about electrical conductivity, imagine a copper wire: it’s nice and conductive. Then you cover it with wax, and it’s not as conductive; you have a barrier,’ Ponder said. ‘The idea was, we really want both: we want the side chains for processing, but we don’t want them in our final material. So, we add side chains that, once we’re done with the processing, we can knock off and wash away.’

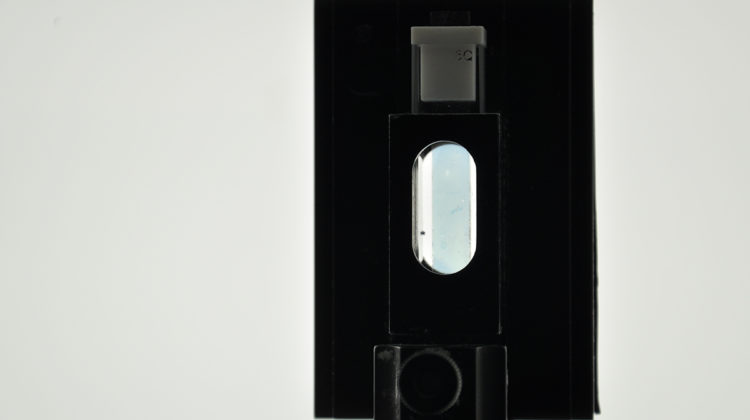

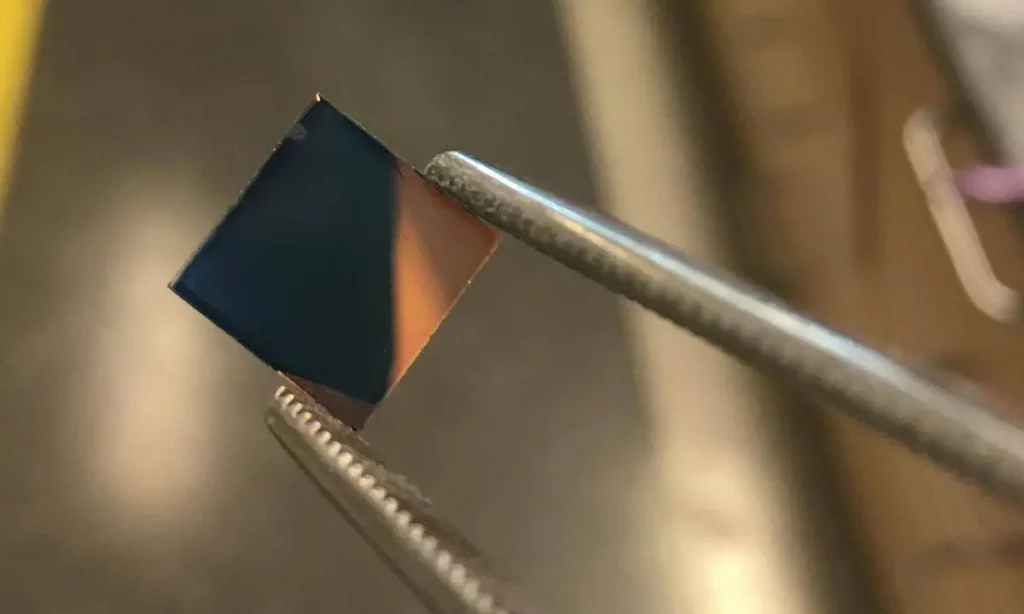

After applying the PEDOT, the researchers chemically cleaved the side chains and then washed them away with common industrial solvents. After a final conversion step, the result is a flexible, transparent, highly conductive (more than 1,000 siemens per centimetre) film that’s stable and now impervious to water or other solvents, which the researchers have dubbed PEDOT(OH).

One of the most widely used transparent conductors for flat panel displays, photovoltaics, smart windows and other applications is indium tin oxide. However, according to John Reynolds, a professor, in the schools of Chemistry and Biochemistry, and Materials Science and Engineering, that material has some drawbacks. ‘It is quite difficult to make curved and flexible devices using indium tin oxide because it’s a brittle material that cracks,’ he said. ‘These polymers we’ve designed are mechanically flexible. There’s an entire area called bioelectronics, where people are putting electronic devices onto skin and into implantable devices, where mechanical flexibility is very important. That’s where these kinds of materials will shine.’

Indium tin oxide must also be used in thin films to balance how it’s prepared with maximum conductivity and transparency. The Georgia Tech team’s material, on the other hand, can be easily processed to create thick films that maintain their conductivity.

‘One real benefit here is that you have a lot of control over how you process the material,’ said Ponder. ‘Industrially, the biggest benefit to this in my mind is that if you want a 20-nanometre film, you can do that. Or if you want a one-micron film – which is 500 times thicker – you can do that, too. You really have a lot more control.’

According to Ponder, other researchers have experimented with breaking off the polymer side chains to boost conductivity, but they usually only removed a few chains and the process wasn’t the main thrust of their research. ‘It’s combining the right type of polymer backbone with the right type of breakable linkage for the right application [in this case, high electrical conductivity],’ Ponder said. ‘For the most part, other researchers haven’t been doing this; they didn’t cleave off enough chains and use a well-designed backbone.’

Reynolds said the simplicity of the team’s polymer was key. ‘Being able to make a very simple, straightforward backbone to this polymer is what really has led to the high level of conductivity,’ he said. The research has been published in the Journal of the American Chemical Society and Angewandte Chemie.